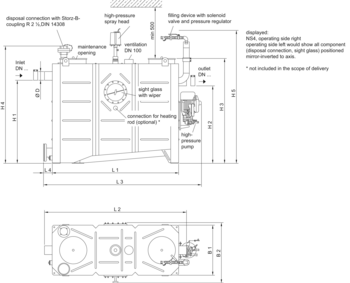

Grease separator LipuJet-S-OM extension stage 2

Product benefits

- Odour-free emptying, cleaning and filling

- Hydromechanical high-pressure cleaning – only a cold-water connection required

- Can be equipped with an disposal pump

- Minimises disposal and maintenance costs thanks to economic step increases in nominal size

- Small delivery dimensions

- Low weight

Product information

- Grease separator plant as per DIN EN 1825 and DIN 4040-100

- For indoors installation – frost free

- With integrated sludge trap

- Operating side: right/left

- Draining connection, fire hose quick coupling B 2½"

- Suction and emptying sump with drain plug socket 1"

- Inspection window with wiper

- Manual operation of the high pressure internal cleaning with pump

- Nominal pressure: 175 bar

- Capacity: 11,6 l/min

- Chopping, mixing, rinsing in one process

- Odour-proof maintenance opening

- Diameter: 300 mm for NS 1 – 4

- Diameter: 500 mm for NS 5.5 – 10

- Filling device with ball valve (connection ¾") for manual refilling

- Electrical connector: 400 V/50 Hz/4,2 kW

Features of base version:

- Emptying and cleaning via maintenance opening

- Odour build-up during emptying and cleaning

Features of upgrade level 1:

- Connection for direct suction

- Odour build-up only during cleaning

Features of upgrade level 2:

- Connection for direct suction

- High pressure cleaning operated manually

- No odour build-up

Features of upgrade level 3:

- Connection for direct suction

- Completely automatic programme

- Optionally with drainage pump and remote control

- No odour build-up

LipuJet-S-OAP (with disposal pump)

Grease layer thickness measuring device

Suitable for

- LipuJet-P

- Oval NS 1 – 10

- Round NS 2 – 22,5

- LipuJet-S

- Oval NS 1 – 10

- Round NS 2 – 20

- LipuSmart-P

- Oval NS 1 – 10

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (80%) and advance warning of fill level (50%)

- With visual display of fill level

- With heated probe rod to increase reliability of operation

- Operating voltage: 230VAC/5 VA

- Max consumption approx. 12W

- Weight: 2.8 kg

ACO Ozone Generator

Suitable for

- Grease separators, indoors

- Grease separators, outdoors

- Lifting stations

- Pumping stations

Description

- ACO Ozone minimizes odors that can arise from grease seperators, lifting plants and pumping stations

- Material: acid-resistant stainless steel

Consists:

- ACO Ozone - ozone generator

- Size (L x W x H): 270 x 100 x 85 mm

- Nominal voltage 230 V / 50 Hz

- Degree of protection IP20

- ACO Ozone pump - feed pump

- Size (L x W x H): 160 x 90 x 90 mm

- Integrated filter

- Nominal voltage 230 V / 50 Hz

- Degree of protection IP54

- ACO Ozone bracket - wall bracket

- Size (L x W x H): 295 x 110 x 90 mm

- Hoses

Message system with GSM module

Suitable for

- All grease separators

- Grease layer thickness measuring device

- Pre-tank plants

- Technical processing systems

- Quatrix-K backflow preventer type 3F

- Sinkamat-K (underfloor) duo

- Muli lifting units

- Pumping stations

- Installation sets

Description

- Parameter via app (Android & iOs)

- Mains-independent alarm via 12V lead-gel battery

- Optical and acoustic alarm message

- Freely configurable inputs

- 6 digital inputs with LED status display

- 1 analogue

- 1 alarm output 12 V

- Alarm forwarding via SMS to mobile phones

- For mounting outside the hazardous area

- Housing: 192 x 150(with cable gland) x 100 mm (WxHxD)

- Protective doctor: IP54

- Operating voltage: 230 V/AC 50/60 Hz

- Weight: 2 kg

Connection cable antenna GSM

Heating rod

Connection box

In-wall frame

Storz coupling for swinging gas lines

Connection box

Suitable for

- Grease separators

- LipuMax-P-D/DM/DA

- LipuJet-P-OD/RD/SD/OM/OMP/RM/RMP

- LipuJet-S-OD/RD/SD/OM/OMP/RM/RMP

- Stach seperators FapuMax-P-DA

- Oil separators Coalisator-P

- LipuLift-P-D/-DA/-DAP

Description

- For evacuation connection DN 80

- Made from stainless steel, material grade 304

- "On wall" version

- Door stop

- Choice of left or right

- Lockable door

- Dimensions (width x height x depth): 370 x 330 x 250 mm

- Weight: 10.4 kg

In-wall frame

Connection box

Suitable for

- Grease separator

- Starch separators

- LipuLift-P-D/-DA/-DAP

Description

- For disposal connection, pendulum gas line (if necessary) and remote control

- From stainless steel, material grade 304

- "Surface mounted” version

- Glass beaded front

- Lockable door, left limit stop

- Dimensions W x H x D: 300 x 725 x 160 mm

- Weight: 10 kg

In-wall frame

Sampling pot DN 100

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 1 – 4

- Starch separator FapuJet-S

- NS 0.5 – 1

- Light oil separator Coalisator-R/-RD

- NS 3

Description

- Stainless steel, material grade 316

- Round shape

- Gradient drop: 70 mm

- For installation in DN 100 horizontal pipes coming from grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 9.9 kg

Sampling pot DN 150

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 5.5 – 10

- Starch separator FapuJet-S

- NS 2

- Light oil separator Coalisator-R/-RD

- NS 6 – 10

Description

- Stainless steel, material grade 316

- Round shape

- Gradient drop: 70 mm

- For installation in DN 150 horizontal pipes coming from grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 12.2 kg

Sampling pot DN 200

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 15 – 20

- Light oil separator Coalisator-E

- NS 20

Description

- Stainless steel, material grade 316

- Round shape

- Gradient drop: 70 mm

- For installation in DN 200 horizontal pipes coming from grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 13.1 kg

Sampling pot DN 100

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 1 – 4

- Starch separator FapuJet-S

- NS 0.5 – 1

- Light oil separator Coalisator-R/-RD

- NS 3

Description

- Stainless steel, material grade 316

- Round shape

- For installation in DN 100 vertical pipes coming from grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 9.5 kg

Sampling pot DN 150

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 5.5 – 10

- Starch separator FapuJet-S

- NS 2

- Light oil separator Coalisator-R/-RD

- NS 6 – 10

Description

- Stainless steel, material grade 316

- Round shape

- For installation in DN 150 vertical pipes coming from grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 11.3 kg

Sampling pot DN 200

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 15 – 20

- Light oil separator Coalisator-E

- NS 20

Description

- Made from stainless steel, material grade 304

- Round shape

- For installation in DN 200 vertical pipes coming from grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 11 kg

Coarse trap DN 100

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 1 – 4

- Starch separator FapuJet-S

- NS 0.5 – 1

Description

- Stainless steel, material grade 316

- Round shape

- Gradient drop: 70 mm

- For installation in DN 100 vertical pipes going to grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 11 kg

Coarse trap DN 150

Suitable for

- Grease separator LipuJet-S/Lipator-S

- NS 5.5 – 10

- Starch separator FapuJet-S

- NS 2

Description

- Stainless steel, material grade 316

- Round shape

- Gradient drop: 70 mm

- For installation in DN 150 vertical pipes going to grease separator

- With EC connector and claw

- Connections tested to DIN EN 877

- Weight: 13.4 kg

Coarse trap DN 200

Stop valve

Suitable for

- Grease separators for free-standing installation

- Starch separator for free-standing installation

Description

- Made of cast iron

- Penstock plate, spindle made from stainless steel, material grade 304

- DN 100

- Length (L): 50 mm

- Spindle travel (H1 – H2): 365 – 465 mm

- Manual wheel diameter: 200 mm

- Weight: 15 kg

Stop valve

Suitable for

- Grease separators for free-standing installation

- Starch separator for free-standing installation

Description

- Made of cast iron

- Penstock plate, spindle made from stainless steel, material grade 304

- DN 150

- Length (L): 60 mm

- Spindle travel (H1 – H2): 478 – 639 mm

- Manual wheel diameter: 200 mm

- Weight: 29.4 kg

Flange connection part

Flange connection part

Operating Logbook

Suitable for

- Grease separator

- For underground installation

- For free-standing installation

Description

- Contents: Check-list and standard forms to document in-house monitoring, maintenance and disposal relating to the plant as required by DIN 4040-100

- Format: A4 with double filing rings

- Size: 60 pages

- Laid out to cover 5 years

- Weight: 0.3 kg