Stainless steel in swimming pools

Stainless steel can provide an outstanding combination of aesthetic appeal, corrosion resistance, strength, durability, and clean ability. Knowledgeable stainless steel selection and maintenance produce outstanding service performance. Swimming pool water may appear passive to the casual user, but the specifier needs to take adequate precautions to ensure any drainage, fittings and fixtures around the pool are manufactured from the correct materials to prevent corrosion.

Corrosion factors

There are many variable factors in swimming pool environments that contribute towards possible corrosion of drainage components:

- Inappropriate stainless steel or finish selection;

- Inadequate or improper maintenance;

- Deficient control of the pool environment;

- Temperature of the pool water;

- pH level of pool water;

- Pool water type: saltwater or fresh water;

- Chlorination level of pool: dosing from hypochlorite (fresh water) or electrolysis (salt water);

- Pool use regularity;

- Proximity of drain to pool: constantly wetted (lapped by the pool), splash zone, change rooms etc.;

- If indoors, the temperature of the room, ventilation and humidity;

This information sheet is intended to advise planners on the various applications possible for drains, channels, covers and lifting units in swimming pools. To ensure that the delivered products maintain their quality, the following points must be clarified in consultation with the planner.

At which pH value can which material be used?

- pH-value between 7.0 and 7.8: material 1.4301 can be used*

- pH-value between 6.8 and 8.2: material 1.4404 / 1.4571 can be used

Which material should be used for which chloride (Cl-)content?

- Material 1.4301 can be used for up to 100 mg/l*

- Material 1.4404 / 1.4571 can be used up to 400 mg/l

- Material 1.4462 can be used up to 2000 mg/l (typical for thermal water)

- Material 1.4547 can be used up to 20000 mg/l (typical for spa applications)

* Material 1.4301 is vulnerable to pit corrosion in contact with clorides. Therefore it may be used only in contact with fresh water (i.e. showers, changing rooms) or in pools with regular maintenance cleaning, excellent water chemistry control, air replacement rates, and humidity control.

If the listed limit values are exceeded, the above-mentioned materials should not be used and a higher-quality material (stainless steel material) may be required.

Comparative values

- Adriatic Sea water with up to 3.8 % salt content ►contains 22 800 mg/l chloride

- North Sea water with up to 3.6 % salt content ►contains 21 600 mg/l chloride

- Baltic Sea water with up to 1.6 % salt content ►contains 9 600 mg/l chloride

General recommendation of material usage

General information

- The materials 1.4301 and 1.4404 / 1.4571 are not suitable for salt water pools.

- The use of 1.4301 is not recommended in the immediate swimming pool area.

- In swimming pools, wellness and sanitary areas, the material 1.4301 can be used if they are regularly flushed with drinking water.

- Slot channels are not suitable as pool overflow channels in areas with swimming pools, chlorine, salt water, etc. (they are suitable for entrance areas, side rooms, changing rooms, catering areas, etc.)

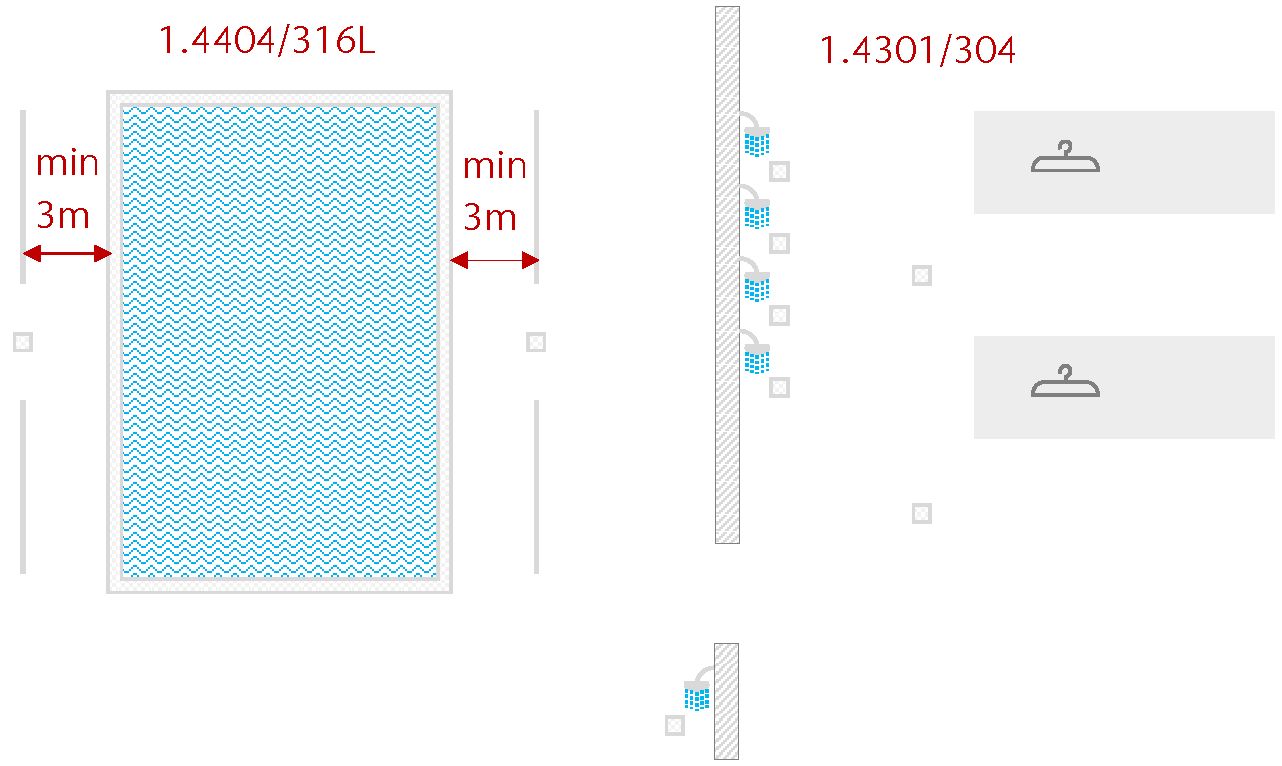

When using channels 1.4404 / 1.4571 in swimming areas, please note

- Distance of the different types of channels to the pool edge approx. 3.00 m

- No flanged channels, designed for on-site welding

- On-site welding only for box channels (as reworking is possible, e.g. grinding, polishing, passivating).

- No flanged slotted channels, as on-site welding is not possible

The following have an influence on corrosion

- the interaction of high temperatures, nitrate, sulphate and chloride concentration

- the structural design and geometry (strongly structured surfaces with gaps and niches on the product)

- Processing (contamination of the stainless steel with other types of steel through grinding, cutting, etc.)

- Chlorine-containing spraying and rinsing water as well as water misting

- Abrasive cleaning agents (do not use)

Care instructions

- Information material: Cleaning and maintenance of stainless steel drainage

- Carefully remove chloride deposits, otherwise there is a risk of pitting corrosion

- To maintain the stainless steel, use chloride-free and hydrochloric acid-free cleaning agents.

- Rinse stainless steel components regularly with clean water

- Observe instructions for daily cleaning