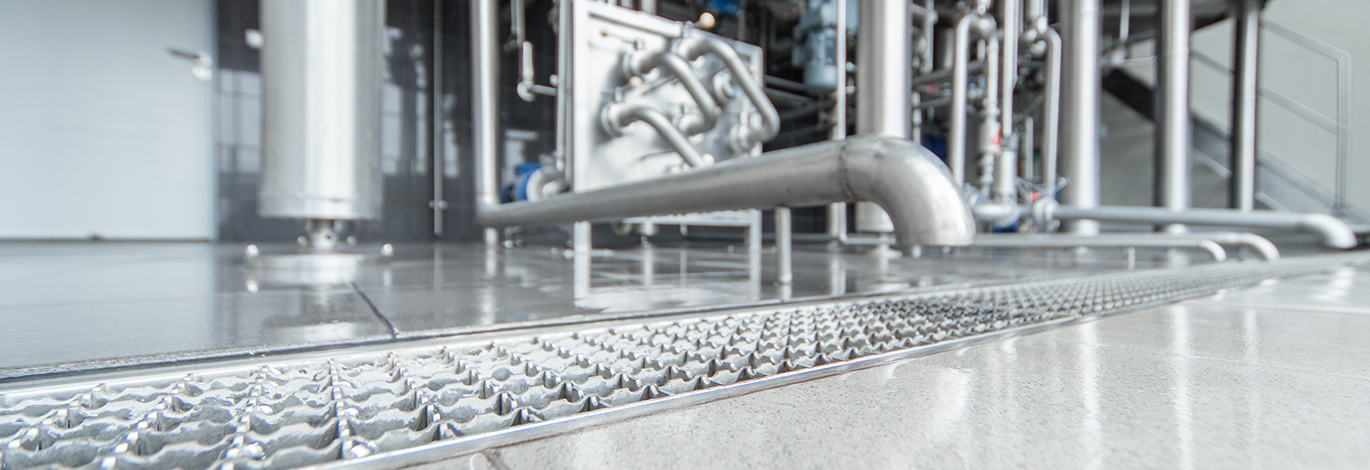

All too often not enough consideration is given to the required capacity and flow rate that the drainage needs to handle now, and may potentially need to handle in the future. Insufficient drainage capacity leads to flooding which compromises health and safety in the workplace and increases the risk of cross-contamination. It’s important to ensure the layout of the drainage matches the layout of the production equipment.

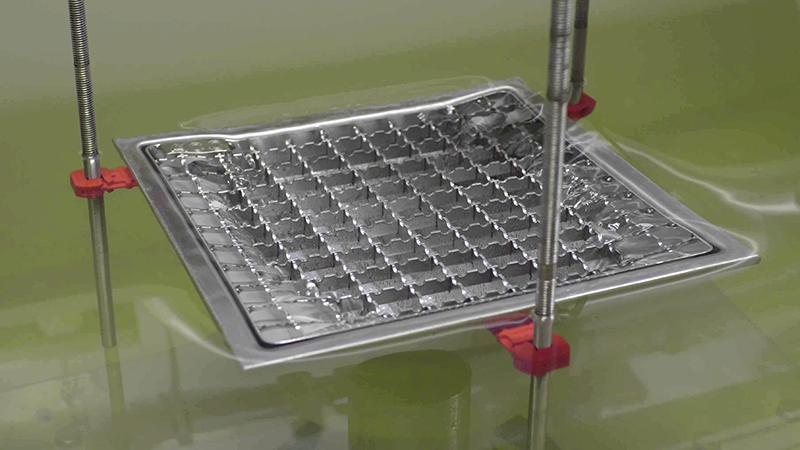

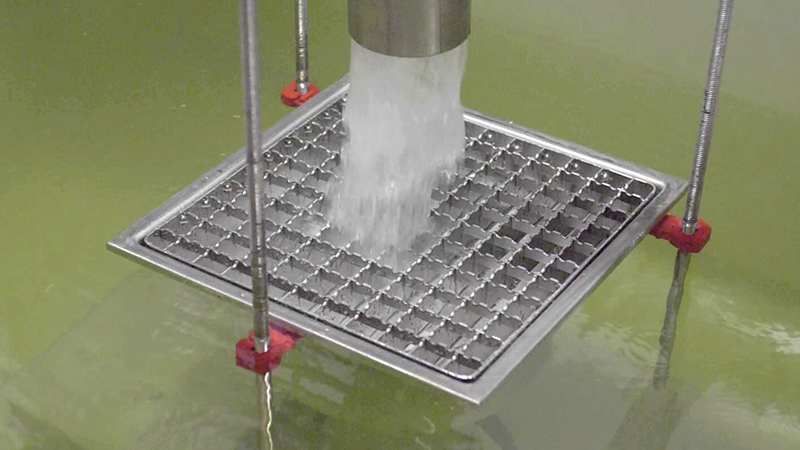

Flow rate is the amount of liquid that comes through drainage in a given time. The default method for measuring flow rates is by EN norm.

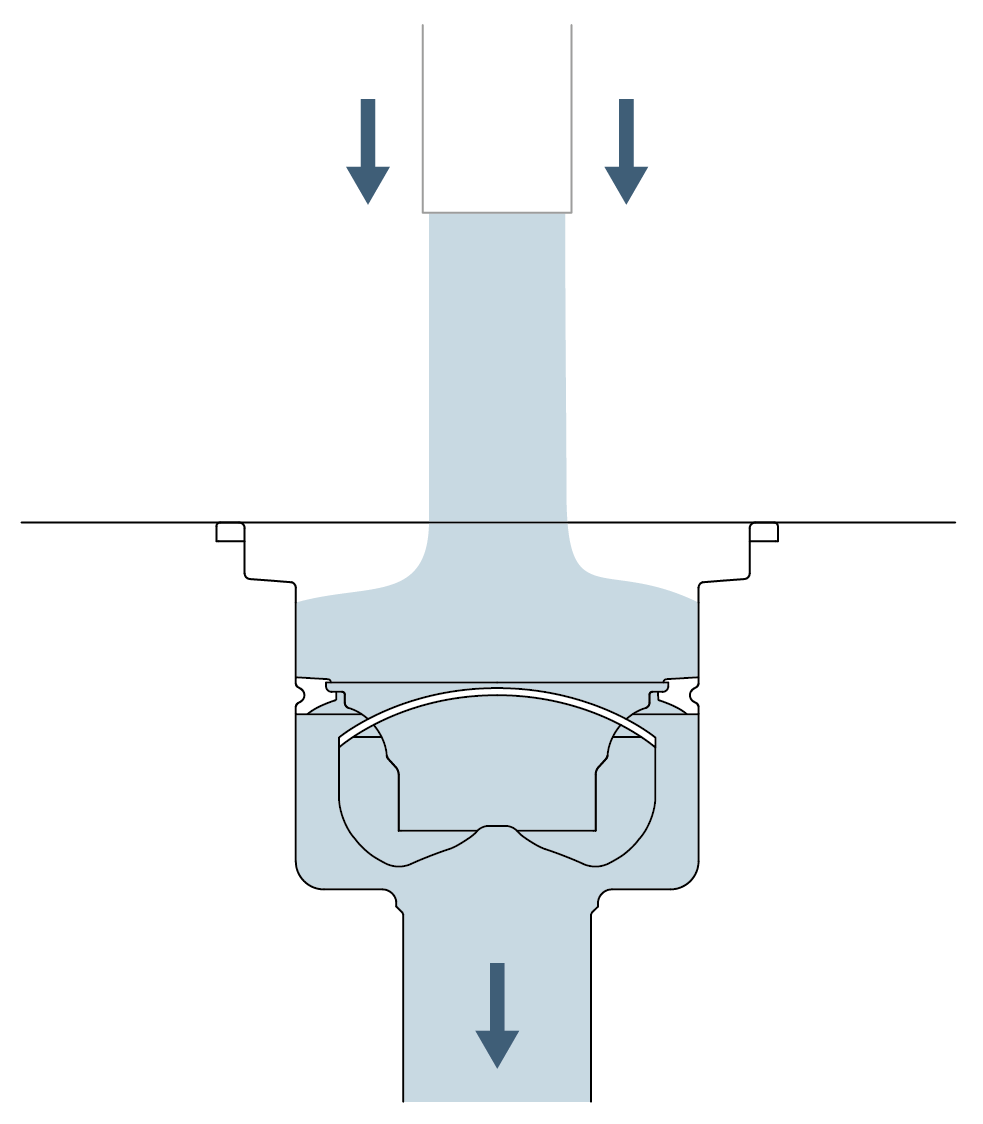

For the specific needs of food and beverage industry, this method is not optimal as machinery outlets are often positioned directly above the drain to make the water flow directly into the gully body. This is because drainage here is not designed to act as an outlet for water on the floor, but as an extension of the wastewater outlet which is discharged directly from machinery. It is also necessary not to spill any water on the surrounding floor.

ACO has developed a methodology to measure ACO gully flow rate. It is crucial for determining the right product solution for use in beverage production and other food and beverage sites. Selecting the right product according to its flow rate can now be carried out more accurately, especially when drainage is used to take in large amount of water at once.