HygieneFirst

Our planet is in the midst of a water crisis like never before.

ACO understands that the global food and beverage sector is operating at the center of this crisis.

Relying on vast and consistent amounts of water, food sector companies are among the first to feel the impact as water becomes increasingly scarce, polluted, and unpredictable.

The industry consumes some 70% of the world’s freshwater to grow and manufacture its products – the business imperative to effectively manage this precious water is becoming abundantly clear.

ACO is one of the world’s leading water tech company and understands the critical role that water management plays in successful commercial food and beverage preparation.

Thanks to Hygiene First and its focus on raising the profile of ultimate hygienic performance, the industry has become much more conscious of the risks and impact of inadequate drainage.

But today, it's not enough to safely and hygienically mass-produce food and beverages to fulfil the needs of an ever-growing population, but also do so in increasingly sustainable yet economical ways.

That’s why to go deeper when it comes to harnessing the power of connected water systems by embracing a more joined up, holistic approach to water management to tackle these challenges.

This approach starts from assessing the current water journey, designing the solution, specification, installation, through to cleaning and maintenance – utilising ACO’s wide portfolio, technical expertise and global presence – to deliver hygienic, economic, ecological and other benefits.

Ultimately these enable food and beverage companies to protect their businesses now from possible reputational, regulatory and physical risks, whilst preserving water for the future.

Food safety features

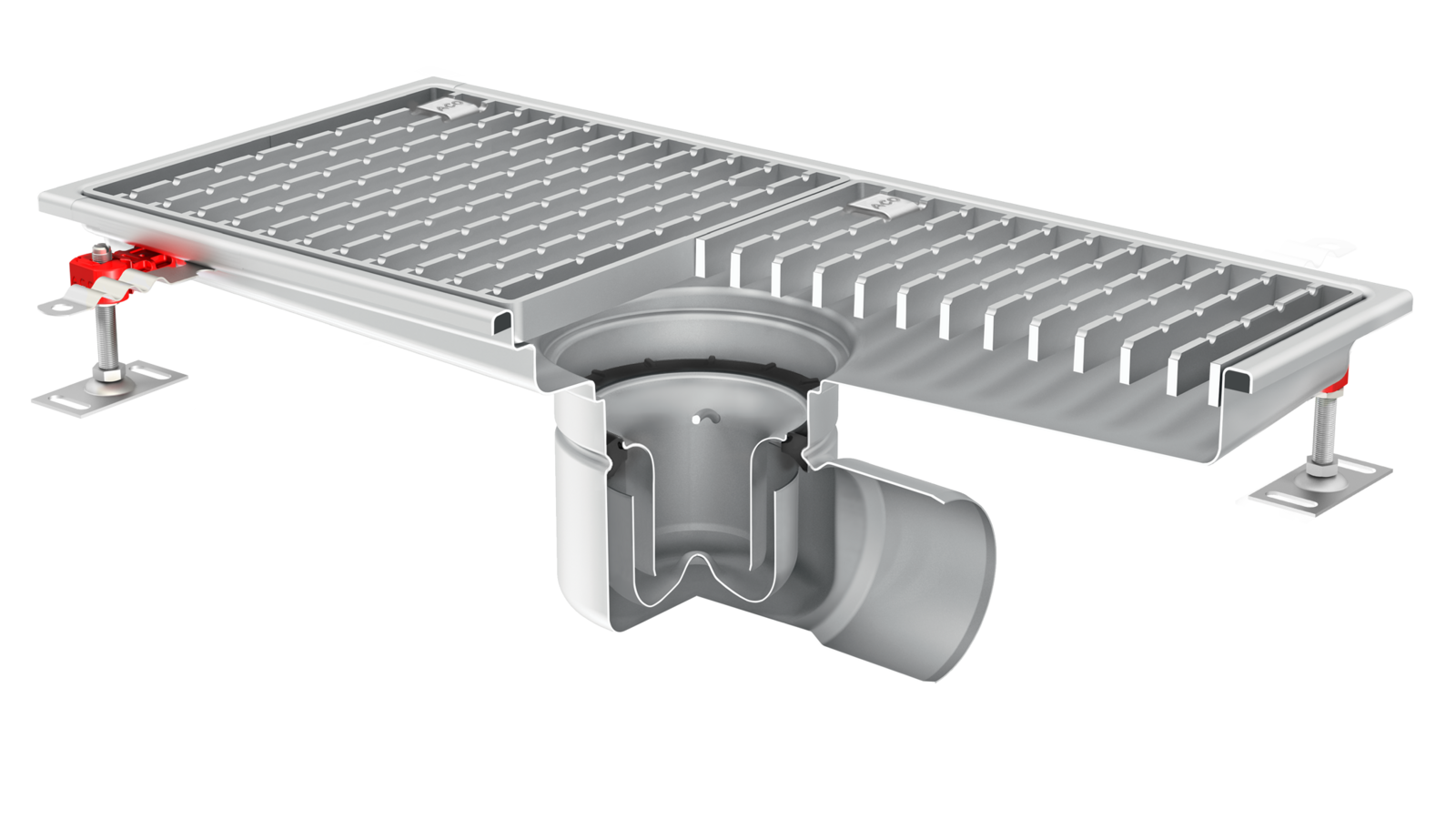

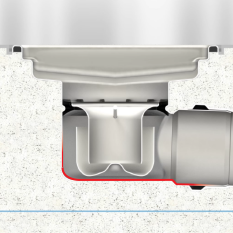

The ACO hygienic drainage system is engineered to meet the most exacting hygienic standards, thereby minimizing the risk of bacterial contamination. To achieve this, we rigorously adhere to the relevant hygiene design principles that are typically reserved for food contact surfaces and are recommended by the European Hygienic Engineering and Design Group (EHEDG).

ACO and the power of hygienic design

Cleanability research findings conducted by the renowned Fraunhofer Institute IVV Dresden in 2016 demonstrated that ACO’s hygienically designed channel dramatically improves cleanability.

The tests showed that the ACO hygienic channel can be cleaned efficiently, without additional mechanical cleaning steps in approximately 8 minutes of cleaning time with 0% residual soiling.

The cleaning of the non-hygienic channel required considerably more effort and it was not possible to completely clean it within the tested cleaning procedure time.

This ultimately helps food and beverage manufacturing companies to improve the safety of their facilites, ensure the quality of their products and reduce cleaning costs and time.

Associated benefits: hygienic design, economic time and cost savings, facility safety