ACO pipe

A reliable stainless steel drainpipe solution

ACO pipe is...

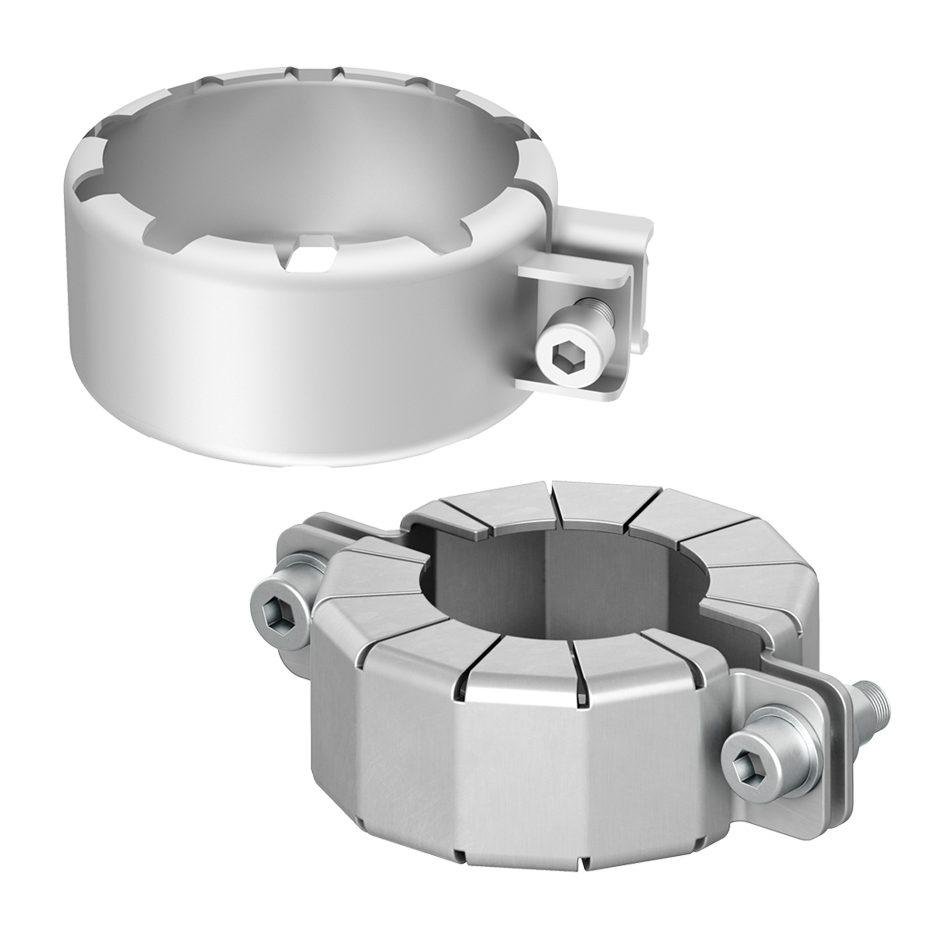

Sagging-proof

- ACO pipe requires less fixing points than both plastic and Cast Iron.

- Plastic: due to the risk of pipe sagging, good fixing is critical in plastic pipes. Requiring more fixing points and more labour.

- Cast Iron: ACO pipe is much lighter when compared to cast Iron, making its fixation easier and quicker.

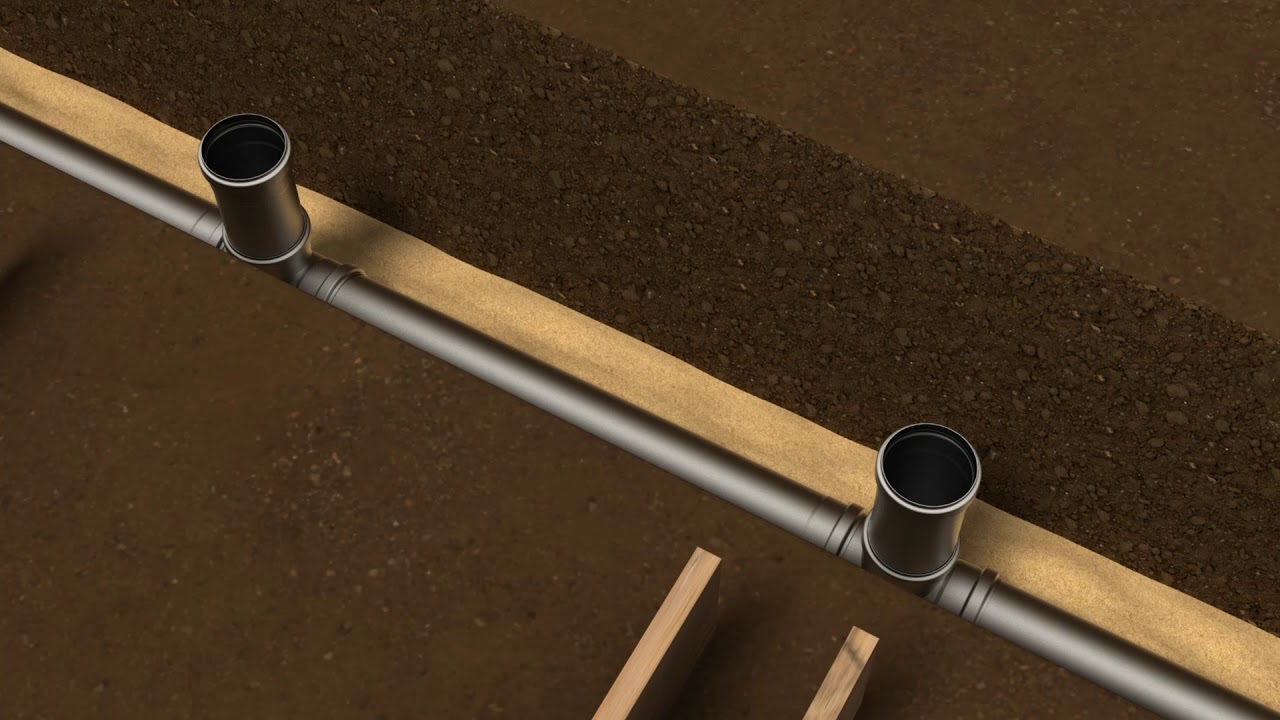

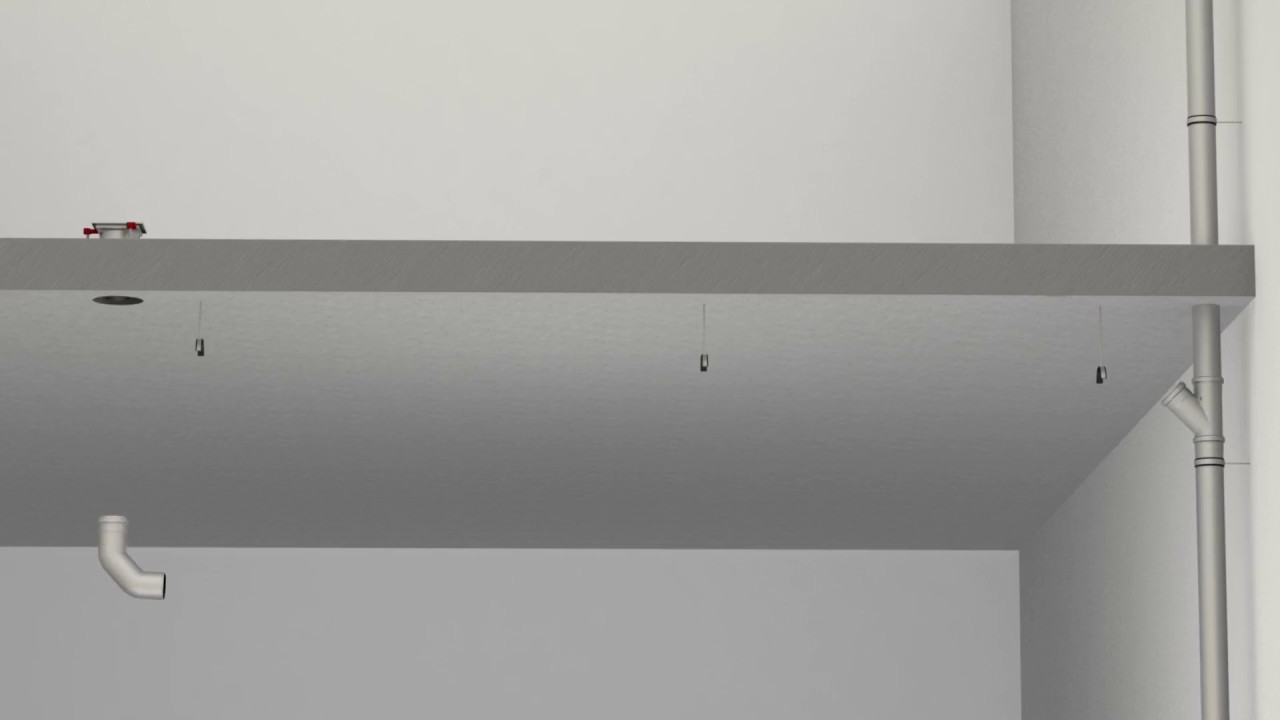

ACO pipe installation

Installation notes

- Thanks to very good thermal expansion features of stainless steel there is no need to install expansion sockets for applications with temperature under 60°C

- For applications where temperature exceeds 60°C we recommend expansion sockets in straight parts each 15 meters

- For applications where temperature exceeds 80°C we recommend expansion sockets in straight parts each 10 meters

- We are ready to help you with all your specific requirements, please contact our customer service

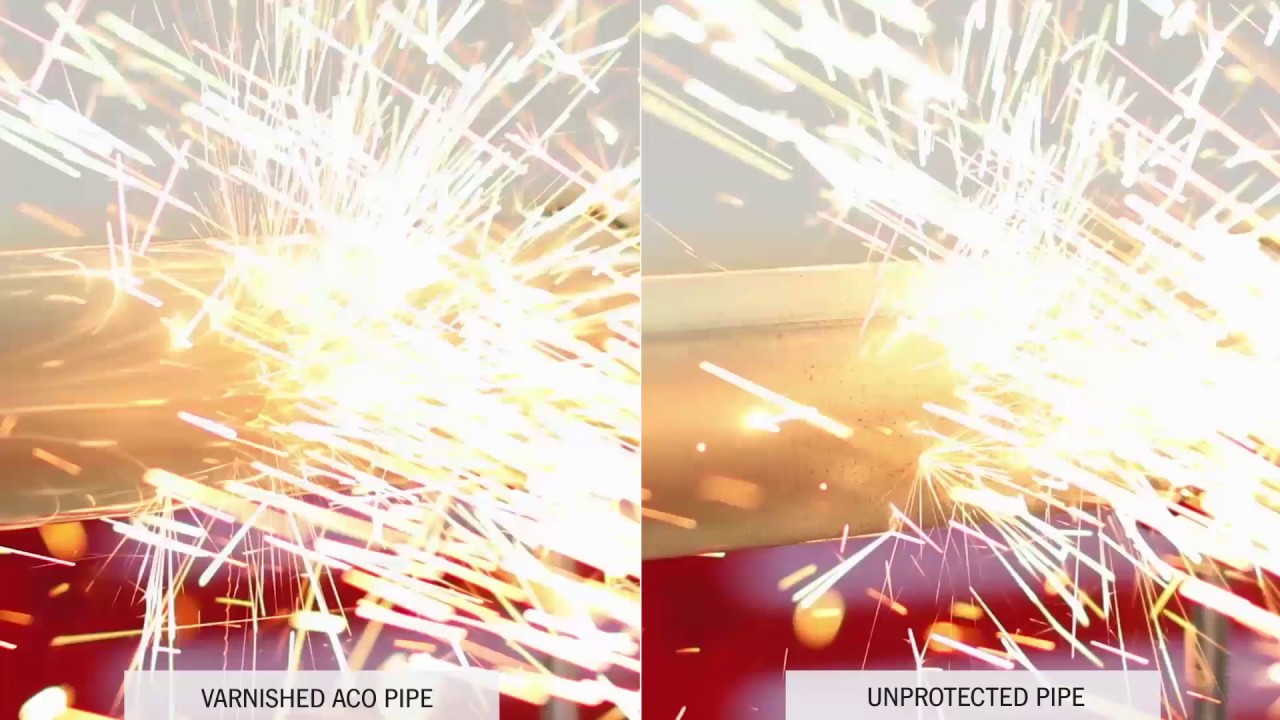

ACO pipe varnished

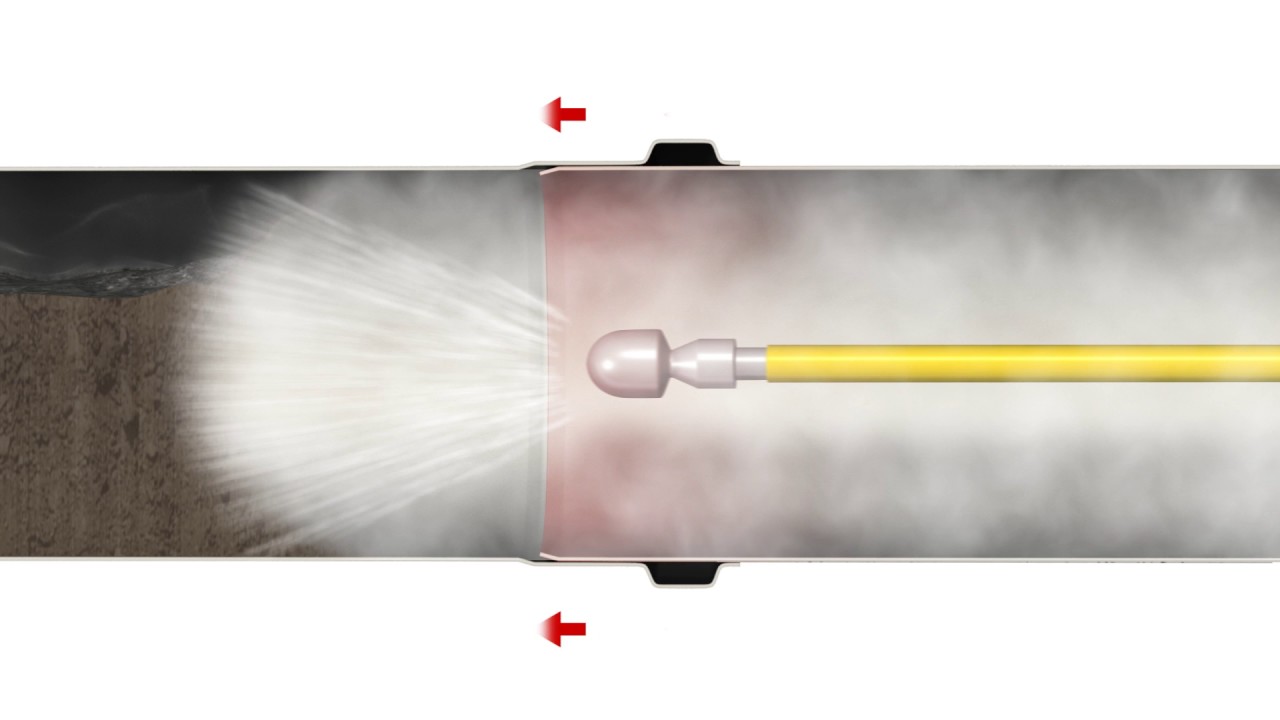

The corrosion of stainless steel due to contact with regular carbonated steel is a well understood risk in the industry. Even micro particles arising from onsite cutting, grinding or welding are sufficient to initiate development of galvanic corrosion, which significantly reduces lifetime of stainless steel components.

Stainless Steel ACO pipes can be ordered with additional layer of protective varnish, designed to protect them from galvanic corrosion due to the contact with carbon steel. The protective feature of varnish acts as a barrier that prevents carbon steel particles from direct contact with stainless steel surface, even during severe exposure. It also increases the overall cleanability of stainless steel piping. Watch the video to learn more.