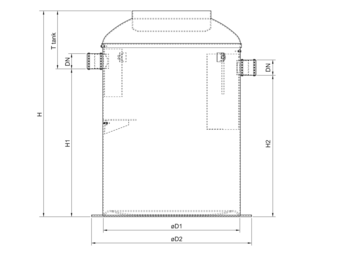

Lipumax G-D

Product benefits

- Simple to install, requires less space

- Top section with odour proof sealed cover

- Integrated connection for sampling device

- Including rubber seal ring for connection with cover plate

Product information

- Tank made of glass reinforced plastic

- With integrated sludge trap

- One-piece construction

- Inner parts made of PEHD

Lipumax G-B (Basic version)

- Disposal and cleaning by opening the cover (associated with the formation of noxious smells)

Lipumax G-D (Extension stage 1)

- Odour-free disposal via a connector to direct suction

- After-cleaning by opening the cover (associated with the slight formation of noxious smells)

- Disposal connection DN65 (flange 75)

Lipumax G-DM (Extension stage 2)

- Manual odour-free disposal/cleaning via direct suction and hydro-mechanic high-pressure inner cleaning

- Disposal connection DN65 (flange 75)

- Filling device with ball valve for re-filling with fresh water

- Hydro-mechanic inner cleaning via high-pressure pump and spray head

Lipumax G-DA (Extension stage 3)

- Programmed, odour-free disposal/cleaning via direct suction and hydro-mechanic high-pressure inner cleaning

- Disposal connection DN65 (flange 75)

- Filling device with soleniod valve for re-filling with fresh water

- Hydro-mechanic inner cleaning via high-pressure pump and spray head

Top sections reduced (600) for grease separators

Top sections for GRP sampling units

Sampling units for GRP separators

Control unit GA 1 + one sensor GA - SG1

Suitable for

GA-1 is an alarm device specially designed for grease separators. They indicate when it is time to empty the grease separator and thus prevents harmful grease emissions to the sewer system.

Description

- Dimensions: 125 mm x 75 mm x 35 mm (L x H x D

- Material: Polycarbonate

- Enclosure: IP65

- Operation temperature: -30 °C...+50 °C

- Supply voltage: 230 VAC ± 10 %, 50/60 Hz

- The device is not equipped with a mains switch

- Power consumption: GA-1: 5 VA, GA-2: 5 VA

- Sensors: 1 or 2 GA-SG1 sensors

- Relay outputs: Potential-free relay output 250 V, 5 A

- 1 pcs for GA-1 Operational delay 10 sec. Relay de-energize

- 2 pcs for GA-2 at trigger point.

- Electrical safety: IEC/EN 61010-1, Class II , CAT II

- EMC: IEC/EN 61000-6-3 (Emission)

- IEC/EN 61000-6-1 (Immunity)

Control unit GA 2 + two senzors GA - SG1

Suitable for

GA-2 is an alarm device for monitoring the thickness of the grease layer accumulating in a grease interceptor and the blocking of the interceptor. The system consists of a GA-2 control unit, two GA-SG1 sensors and a cable joint.

Description

- Dimensions 125 mm x 75 mm x 35 mm (L x H x D)

- Package 1,2 kg (control unit + 2 sensors + cable joint)

- Enclosure IP 65, material polycarbonate

- Cable glands adjustment range 6-10 mm

- Operation temperature -30 ºC...+50 ºC

- Supply voltage 230 VAC ± 10 %, 50/60 Hz

- The device is not equipped with a mains switch

- Power consumption 5 VA

- Sensors 2 pcs GA-SG1 sensors

- Relay output 2 pcs potential-free relay outputs

- 250 V, 5 A Operational delay 10 sec.

- Relay de-energize at trigger point.

- Electrical safety IEC/EN 61010-1, Class II , CAT II

- EMC Emission IEC/EN 61000-6-3

- Immunity IEC/EN 61000-6-1