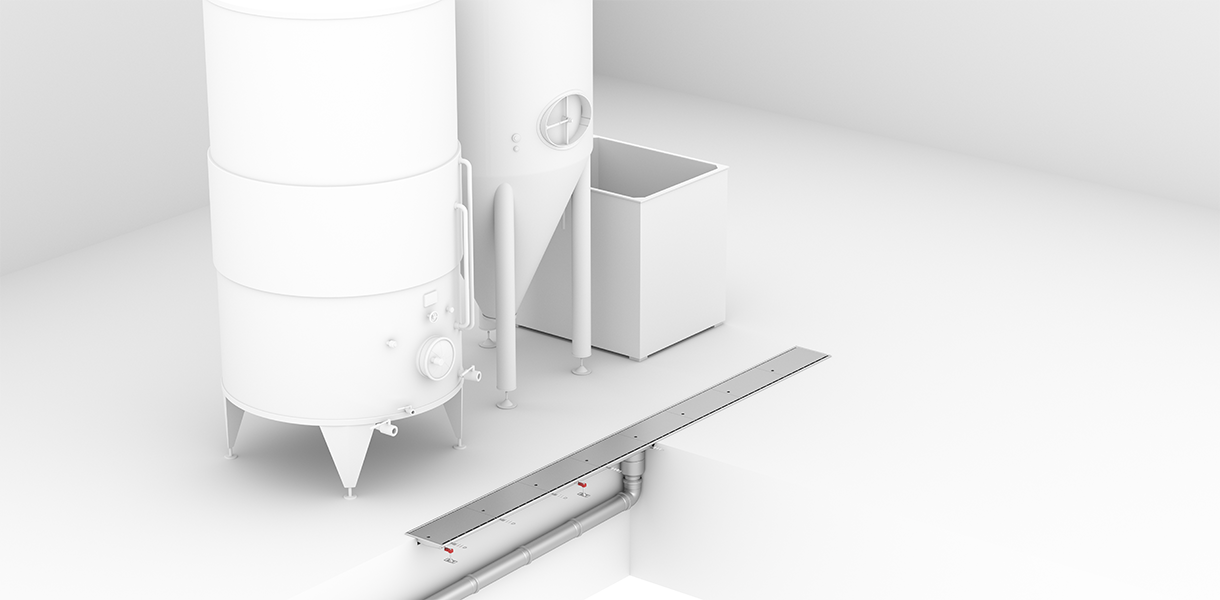

Drainage system components

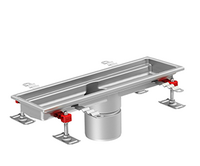

ACO hygienic box channel - narrow

Hygienic box channels are available also in 150 mm width. This space-saving solution keeps all hygienic and cleanability features as all other hygienic box channels from ACO portfolio.

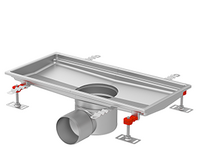

ACO hygienic box channel

ACO's hygienically designed box channels provide easily cleanable and fully inspectable drainage solutions that meet stringent cleanability requirements and are capable of handling large volumes of fluid which contains solid particles.

ACO slot cover grating

ACO’s fully hygienic slot covers fulfil the most stringent cleaning requirements. Slot covers are perfect solutions for places where heavy loads and small wheels are operated.

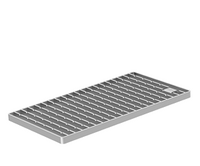

ACO hygienic ladder grating

ACO's hygienically designed ladder gratings provide an easy-to-clean solution for breweries. Ladder gratings are suitable for use in applications which are subject to high load classes and waste water which contains solid particles.

ACO pipe

ACO’s stainless steel push-fit pipe system is designed for grey or black water applications. ACO Pipe products offer more than 40 years’ product life thanks to the material properties of stainless steel. Easy on-site installation and handling is ensured by a push-fit assembly system and related cutting tools.