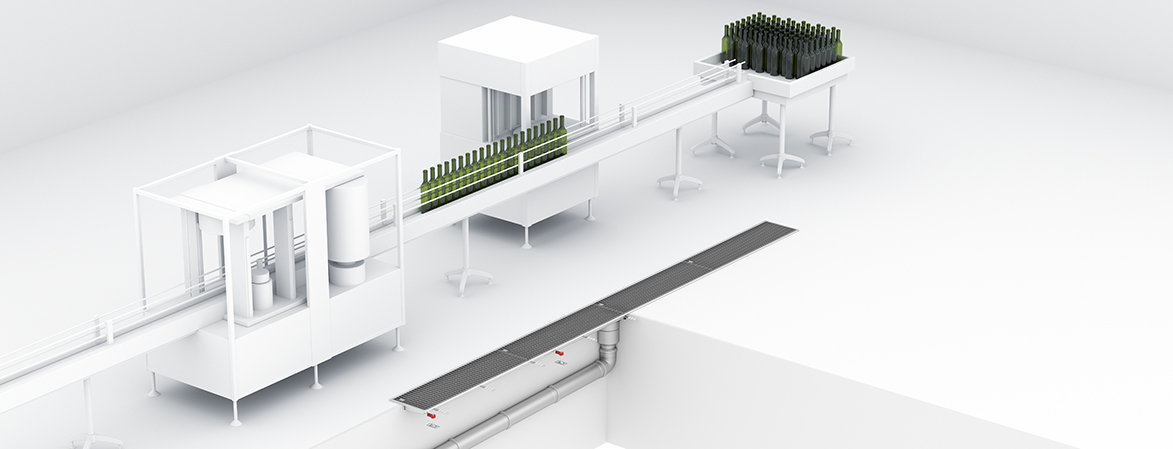

We can help you, but you have to consider the future usage of your drains in advance. If the drainage is incorrectly specified, there's a risk that drains will become blocked. To maintain the performance of your drainage systems and your production facility, it's important to consider at the very beggining how you will use the drainage on a daily basis. Below, you can find an effective drainage solution which is designed specifically for bottling areas:

Drainage system components

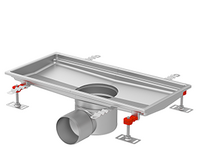

ACO hygienic box channel

ACO's hygienically designed box channels provide easily cleanable and fully inspectable drainage solutions that are ideal for applications with stringent cleanability requirements and large volumes of fluid which contains solid particles.

ACO silt basket

For the collection of solid particles, ACO drainage systems can be supplied with an optional silt basket. ACO silt baskets are available in a wide variety of capacities ranging from 0.3 litre to 9.5 litres.

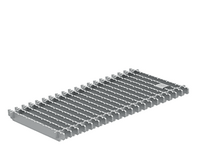

ACO frameless ladder grating

The ACO frameless ladder gratings provide fully hygienic solutions thanks to the robotic welding technology used during the production. Frameless design ensures that no debris is captured between the grating and drainage.

ACO kerb

ACO kerb products provide reliable wall protection that prevents walls from impacts, water or chemical ingress, or other damage associated with the traffic and production process. They are suitable for any food processing area. ACO kerbs are available in polymer concrete and stainless-steel variations.

ACO pipe

ACO’s stainless steel push-fit pipe system is designed for grey or black water applications. ACO Pipe products offer more than 40 years’ product life thanks to the material properties of stainless steel. Easy on-site installation and handling is ensured by a push-fit assembly system and related cutting tools.