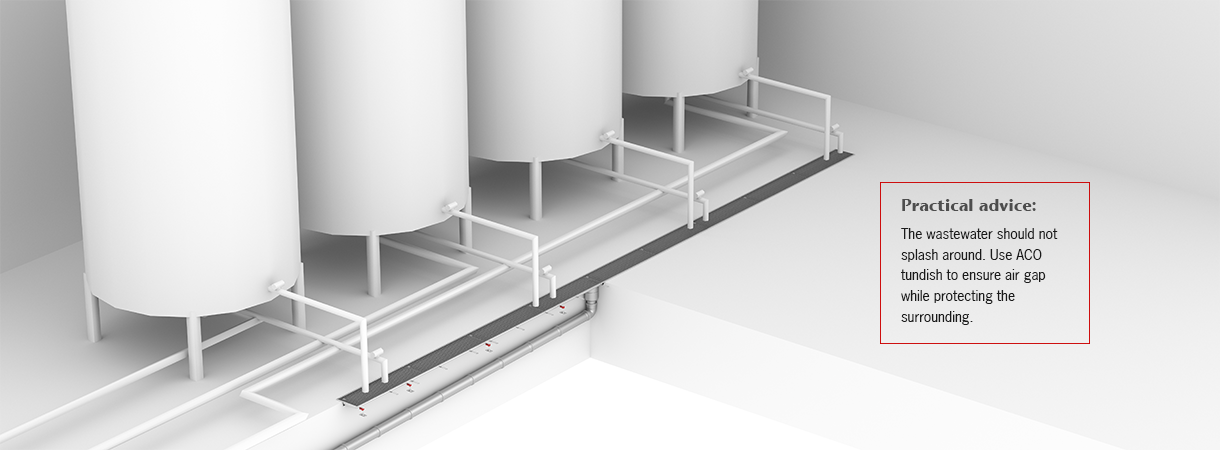

We recommend you to position your stainless steel drainage directly beneath the outlets of CIP stations. But do not forget to consider the drainage capacity, to ensure you have an air gap and that the drainage can be easily inspected.

It is essential that the layout of the drainage system and production equipmentis considered holistically at specification stage and that a hygienically designed, high capacity drainage system is used if large volumes of waste water are to be handled effectively.

Drainage system components

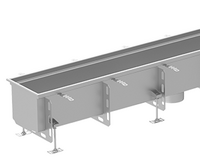

ACO hygienic box channel - extra deep, with flexible joint to the floor

Extra deep variations of ACO hygienic box channels provide extended flow rates and higher retention capacities without compromising hygiene. Extra deep hygienic box channels are designed to handle waste water from such a demanding technologies like CIP systems or fermentation tanks.

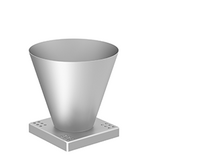

ACO hygienic gully - high capacity, with flexible joint to the floor

Hygienic gully in its high capacity variation has a diameter 440 mm and is capable of handling flow rates of more than 20l/s. That makes it suitable for the most demanding applications such as CIPs.

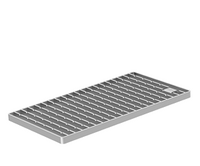

ACO mesh grating

ACO mesh grating is a lightweight economical solution for areas with low hygienic risk and load class resistance demands.

ACO hygienic ladder grating

ACO's hygienically designed ladder gratings provide an easy-to-clean solution for breweries. Ladder gratings are suitable for use in applications which are subject to high load classes and waste water which contains solid particles.

ACO pipe

ACO’s stainless steel push-fit pipe system is designed for grey or black water applications. ACO Pipe products offer more than 40 years’ product life thanks to the material properties of stainless steel. Easy on-site installation and handling is ensured by a push-fit assembly system and related cutting tools.