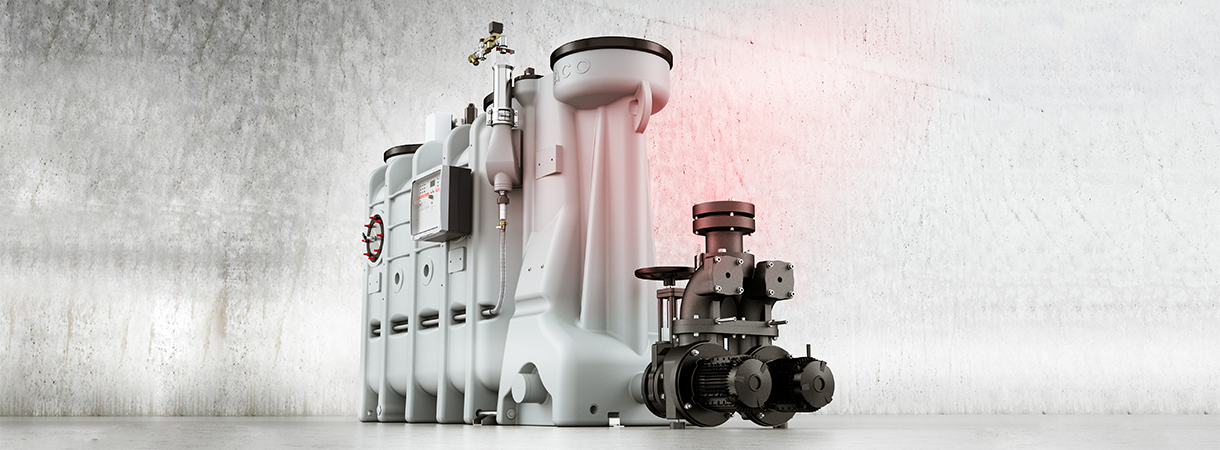

ACO LipuSmart

Full disposal grease separator with integrated lifting plant

The ACO LipuSmart grease separator integrates the functions of grease separation, sampling, drainage using a lifting plant and a control system into one product.

Pressure sensors monitor the level of the separator and lifting plant. The plant control unit analyses both sensors and shows the filling level with centimeter precision in the display. If necessary, the pumps are switched on and off or the overflow alarm is triggered. The ACO air bubble injection in the separator and the lifting plant prevents the grease layer from hardening in the pneumatic pipe and causing blockages. The optional grease layer thickness measurement sensor, which can be connected to the building control system, guarantees smooth operation.

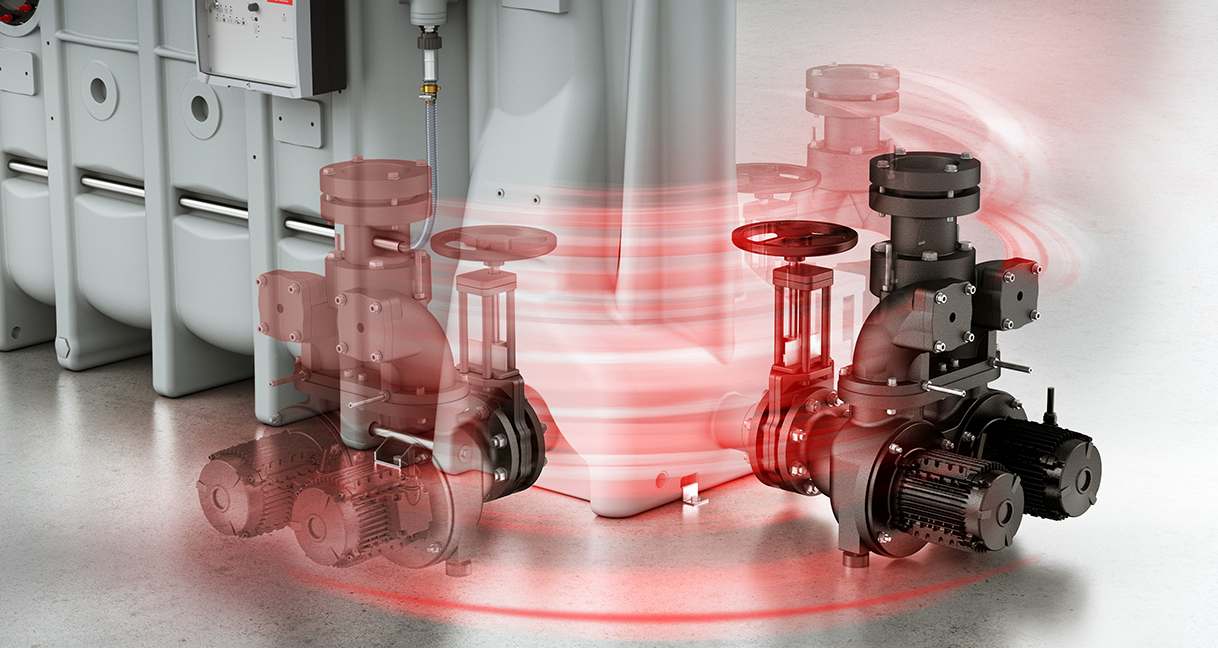

The LipuSmart pump equipment was specially developed by ACO in collaboration with the Institute for Process Machines and Plant Equipment (IPAT) so that the pump efficiency could be optimized. The design also benefits from a reduction in the sound pressure level and significantly reduces the risk of blockages. Unpleasant odours are avoided thanks to hydro-mechanical high-pressure inner cleaning. The horizontal and vertical rotating orbital cleaning head from extension stage2 and 3 guarantees intensive cleaning of the inside walls. During this process, the compressor generates a pressure of 150 bar which completely homogenises the grease layer.

4 products merged in 1 solution

Thanks to the powerful integrated separator and pump equipment, and the direct sampling option, the ACO LipuSmart greatly reduces the amount of planning and layout work required. The control unit for the general system combines the individual control units of the grease separator and the lifting plant into one complete unit.

Thanks to its clear menu structure, the graphic presentation of the grease separator disposal processes, a logging function and the signalling unit with a GSM module, the control unit for the general system facilitates operation of the plant. The Bluetooth interface that is standard from extension stage 3 can also be replaced with the Modbus as an option. The inspection window allows additional control of the grease separator contents.