Grease separators are essential in any setting where animal or vegetable fats enter the wastewater system. In commercial kitchens, pre-treatment plants are a necessity. These systems prevent solids and liquids that can release harmful or unpleasant vapors, or otherwise interfere with operations, from being discharged into the public sewerage network.

Without these pre-treatment systems, fats, oils, and grease (FOG) in the wastewater pose significant risks. They can accumulate on the walls of pipes, leading to corrosion, blockages, and unpleasant odors. Additionally, they can damage the pipe system, drainage equipment, and the broader sewer network.

Proper use of grease separators ensures the longevity and efficiency of your plumbing and helps maintain a safe and hygienic environment in your kitchen.

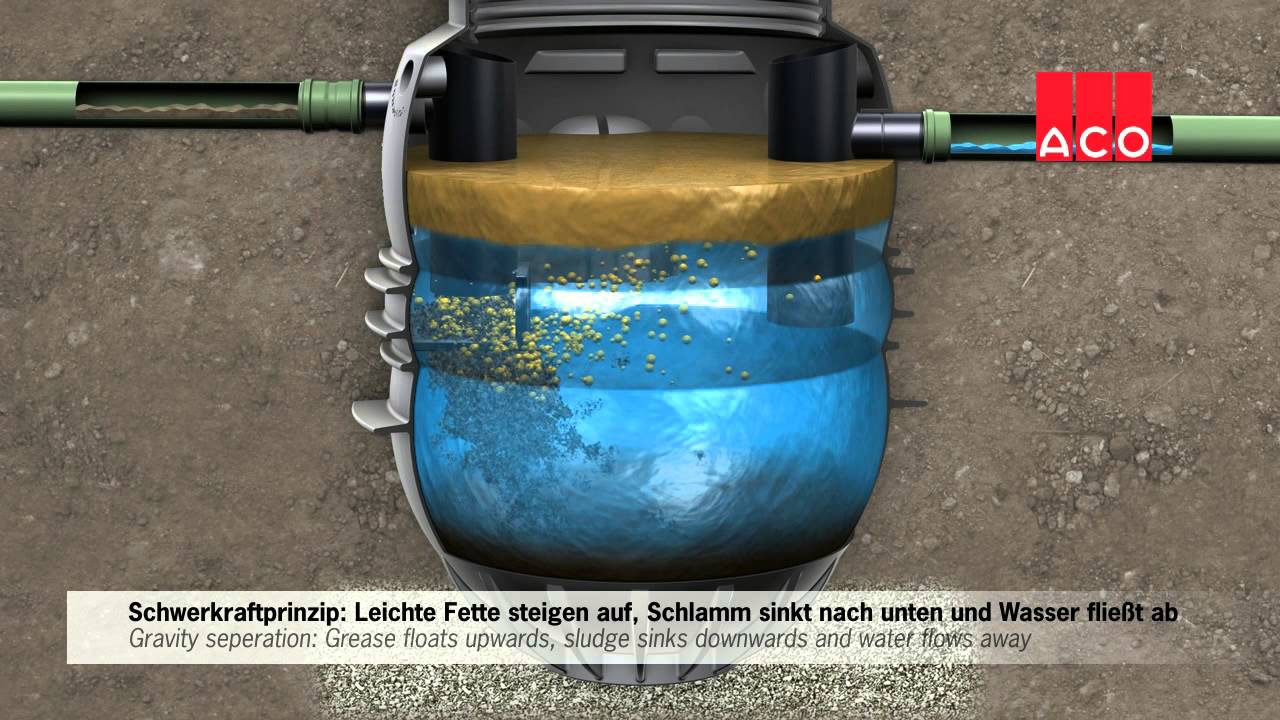

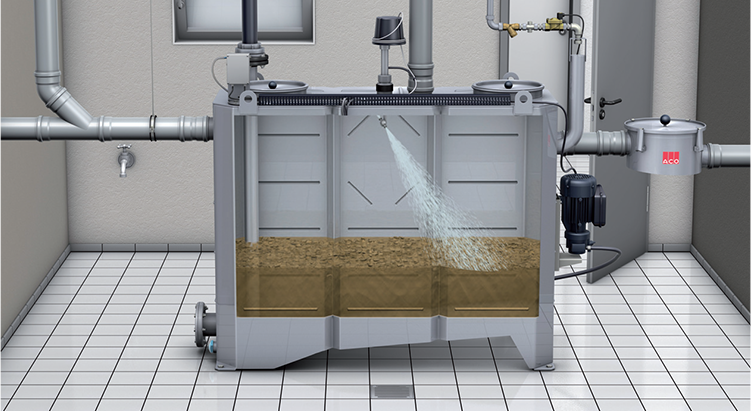

Grease separators work using gravity. Their different densities are used to separate the fat/oil from the wastewater. Animal and vegetable fats and oils have a lower specific gravity than water, which makes them rise to the surface. Depending on the grease separator system the separated substances can be disposed of correctly either separately or together with the total contents of the grease separator.

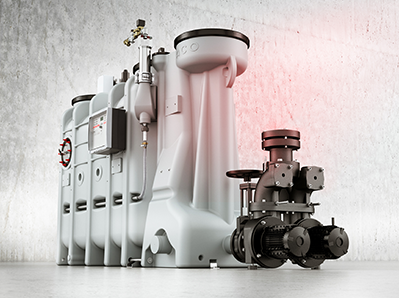

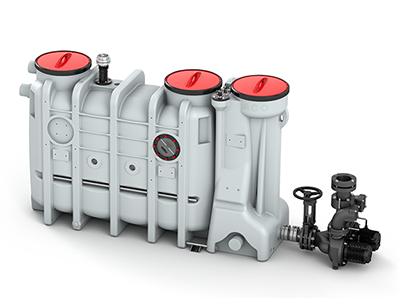

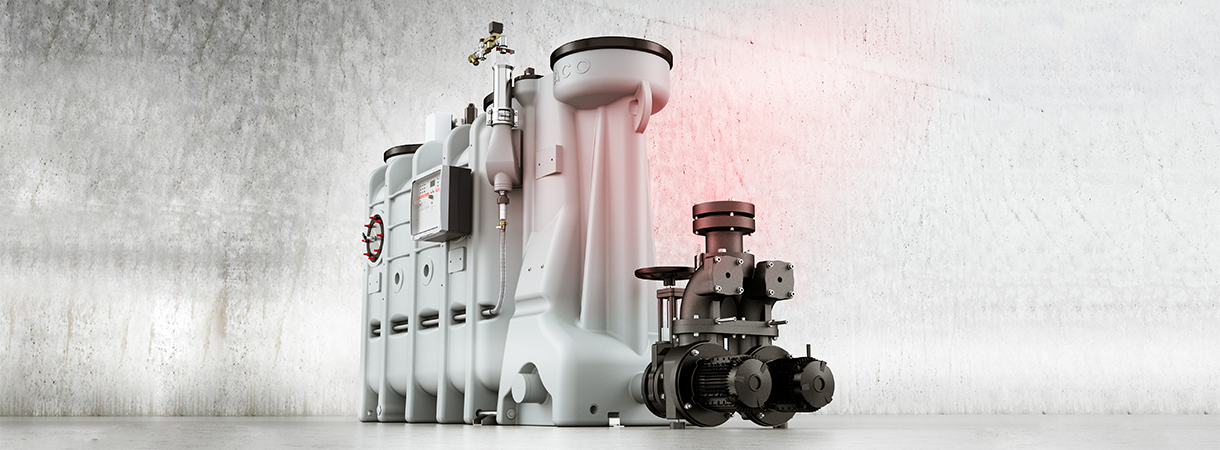

ACO Building Drainage offers their customers grease separator plants for free-standing or underground installation. In addition, we distinguish between full disposal and partial disposal plants. With full disposal the content of the separator is removed, cleaned and filled by a disposal company at regular intervals. With partial disposal the separated grease/oil as well as the sludge are collected in separate containers and disposed of separately.

ACO offers comprehensive range of nominal sizes of grease separators for both free-standing installation and below ground installation that are not available from other manufacturers. This means the perfect solution can be provided according to the level of waste water to be dealt with and there is no need to take the next highest nominal size for reasons of capacity, which saves money and space.

In order to reduce microbes, very hot water is used for rinsing in hospitals, catering facilities and homes for senior citizens in particular, with the separator logically being exposed to that same water. The same applies to the emptying of tilting frying pans and boilers. Grease separators made of stainless steel are ideally suited to such tasks and can prevent deformations in the long term.

Stainless steel belongs to building material class A1, so it does not represent any fire load or fire hazard. A kitchen planner should aim to reduce the fire load in a building as far as possible and guarantee high safety standards.

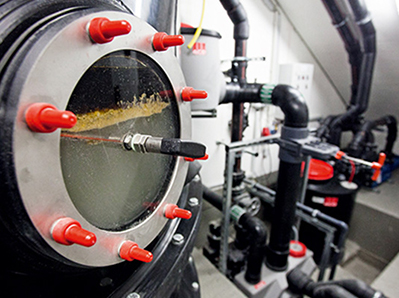

Furthermore, irrespective of the material, a large selection of extension stages are available, each of which can increase operational and cleaning safety.

This is achieved by additional components such as systems for inner cleaning, as well as filling devices and disposal pumps. Measuring devices are also able to monitor operating conditions and reliably forward them to corresponding monitoring devices.

Different separators are available for the various applications found in the field, which are manufactured specifically for particular requirements or building situations, whether they are found in new buildings or renovation projects. ACO provides grease separator systems as a complete solution for a range of application areas ranging from snack bars right up to large commercial and industrial kitchens.