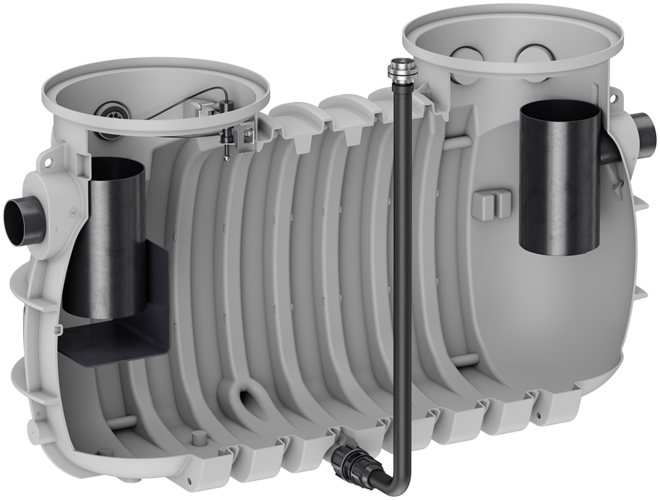

LipuMax-PF-H-DA Stage 3

Product benefits

- Grease separator with integrated sludge trap in a single tank

- Reduced/simplified installation work

- Emptying, cleaning and filling the grease separator without unpleasant odours

- Automatic operation of the disposal process

- Control unit including remote control for outdoor installation

Product information

Grease separator

- Grease separator in accordance with EN 1825 Nominal Size 10, 15 and 20

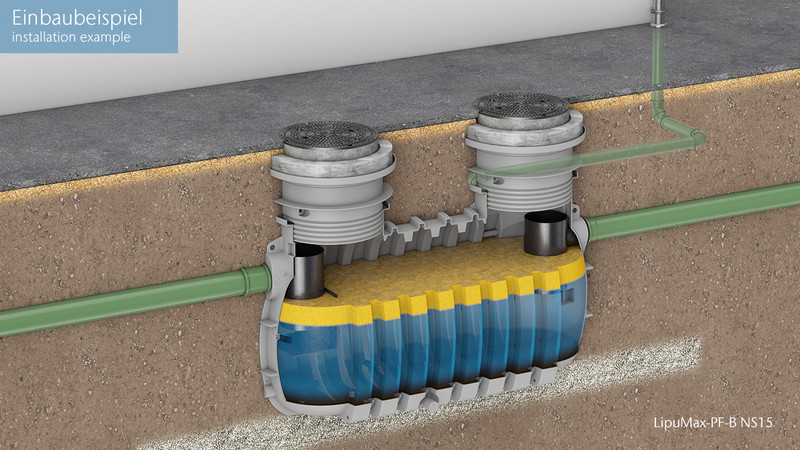

- For underground installation

- With integrated sludge trap

- 2 x maintenance openings Ø 840 mm for the respective accommodation of a required extension system characteristic dimension 800 or 800 - 600 (accessories) with load classes A 15, B 125 or D 400

- Maximum inlet invert ZT up to approx. 1.90 m after extension system (distance from top edge of ground to lower edge of connection port/pipe bottom)

- Maximum installation depth ET up to 3 m (distance from top edge of ground to lower edge of tank)

- Buoyancy safety of the tank: Buoyancy-proof up to 1.65 m above the lower edge of the tank with extension system and load distribution plate (for A 15, B 125 / D 400)

- Control unit for frost-free installation with connecting cable 1.5 m and CEE plug 16 A including phase inverter, protection class IP 54

- Remote control for frost-free installation, protection class IP 54

- Declaration of Performance (DoP) No: BD/G1/-1024

- Internal jetting:

- High-pressure spray head (360° cleaning) with connection cable 30 m

- HP (high pressure) pump (nominal pressure 175 bar) with reservoir for frost-free installation

- High-pressure hose 2.7 m long for connecting HP pump and filling line connection

- Required high-pressure hose (accessories) 10, 20 or 30 m long for connecting the high-pressure spray head and the filling line.

- Filling unit (components with DVGW and KIWA approvals) for frost-free installation for automatic refilling:

- Free-flow valve

- Pressure reducer with dirt traps

- Solenoid valve

- Pipe elbow

- Connection parts for on-site disposal line:

- 1x Compression fitting DN 80/ 65 (OD 90/ 75 mm)

- 1 x Compression fitting DN 65 (OD 75 mm)

- Pipe (OD 75 mm) with fixed coupling Storz-B / 2½" and blind coupling

- Connection parts for on-site filling, supply (cable conduit) and vent stacks:

- 3 x Socket seal DN 100

- 1 x Cable gland

- Pipe branch

Connections

- Pipe connections:

- Horizontal pipe socket DN 150 / OD 160 mm (NS 10) or DN 200 / OD 200 mm (NS 15/20) for on-site supply line

- Horizontal pipe socket DN 150 / OD 160 mm (NS 10) or DN 200 / OD 200 mm (NS 15/20) for on-site drain line

- 8 x horizontal pipe sockets (closed) DN 100 / OD 110 mm for on-site filling, supply (cable conduit) and ventilation lines

- 1 horizontal pipe socket each (closed) DN 80 / OD 90 mm arranged on the right and left in the direction of flow for on-site disposal line

- Water connections (30 l/min):

- Internal thread ¾" on filling unit for on-site cold water line

- External thread ¾" on the storage tank HP pump for on-site cold water line

- Electrical connection:

- 400 V / 50 Hz / 4.2 kW

- General fuse protection: 3 x 16 A (time lag) or according to local conditions.

- The power supply must comply with the directives of the local power supplier. Particular attention should be paid to the specific protection measures and the cable cross-sections and potential compensation.

Top sections standard for separators

Sampling shafts set 450

Sampling shafts body 800

Disposal shafts

Grease layer thickness measuring device

Suitable for

- Grease separator LipuMax-P for underground installation

- LipuLift-P

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (100%) and advance warning of fill level (80%)

- With visual display of fill level for advance warning and full warning

- With heated probe rod to increase reliability of operation

- Operating voltage: 230 V/50 Hz

- Max consumption approx. 12W

- Cable length: 10 m

- Weight: 6.4 kg

- Rabattgruppe: 11

Grease layer thickness measuring device

Suitable for

- Grease separator LipuMax-P for underground installation

- LipuLift-P

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (100%) and advance warning of fill level (80%)

- With visual display of fill level for advance warning and full warning

- With heated probe rod to increase reliability of operation

- Operating voltage: 230 V/50 Hz

- Max consumption approx. 12W

- Cable length: 20 m

- Weight: 7.8 kg

- Rabattgruppe: 11

Grease layer thickness measuring device

Suitable for

- Grease separator LipuMax-P for underground installation

- LipuLift-P

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (100%) and advance warning of fill level (80%)

- With visual display of fill level for advance warning and full warning

- With heated probe rod to increase reliability of operation

- Operating voltage: 230 V/50 Hz

- Max consumption approx. 12W

- Cable length: 30 m

- Weight: 9.6 kg

- Rabattgruppe: 11

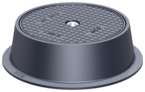

Road cap

Suitable for

- Grease separator for underground installation

- LipuMax-P-D

- LipuMax-P-DM

- LipuMax-P-DA

- Stach separators FapuMax-P-DA for underground installation

- Oil separators Coalisator-P

Description

- Shaft cover tested to DIN EN 124/DIN 1229

- Load class: A 15

- Frame and cover made of cast iron

- Diameter: 300 mm

- Clear width: 250 mm

- Weight: 9.8 kg

- Rabattgruppe: 1

Top sections standard for separators

Sampling shafts set 450

Sampling shafts body 800

Disposal shafts

Grease layer thickness measuring device

Suitable for

- Grease separator LipuMax-P for underground installation

- LipuLift-P

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (100%) and advance warning of fill level (80%)

- With visual display of fill level for advance warning and full warning

- With heated probe rod to increase reliability of operation

- Operating voltage: 230 V/50 Hz

- Max consumption approx. 12W

- Cable length: 10 m

- Weight: 6.4 kg

- Rabattgruppe: 11

Grease layer thickness measuring device

Suitable for

- Grease separator LipuMax-P for underground installation

- LipuLift-P

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (100%) and advance warning of fill level (80%)

- With visual display of fill level for advance warning and full warning

- With heated probe rod to increase reliability of operation

- Operating voltage: 230 V/50 Hz

- Max consumption approx. 12W

- Cable length: 20 m

- Weight: 7.8 kg

- Rabattgruppe: 11

Grease layer thickness measuring device

Suitable for

- Grease separator LipuMax-P for underground installation

- LipuLift-P

Description

- For electronic measurement of layer of grease

- Suitable for liquid and/or congealing grease

- Measuring device with plug and used connecting cable, length: 3 m

- With two voltage-free changeover contacts to display full warning (100%) and advance warning of fill level (80%)

- With visual display of fill level for advance warning and full warning

- With heated probe rod to increase reliability of operation

- Operating voltage: 230 V/50 Hz

- Max consumption approx. 12W

- Cable length: 30 m

- Weight: 9.6 kg

- Rabattgruppe: 11

Road cap

Suitable for

- Grease separator for underground installation

- LipuMax-P-D

- LipuMax-P-DM

- LipuMax-P-DA

- Stach separators FapuMax-P-DA for underground installation

- Oil separators Coalisator-P

Description

- Shaft cover tested to DIN EN 124/DIN 1229

- Load class: A 15

- Frame and cover made of cast iron

- Diameter: 300 mm

- Clear width: 250 mm

- Weight: 9.8 kg

- Rabattgruppe: 1