By taking a rounded approach, we are helping our clients all around the world with:

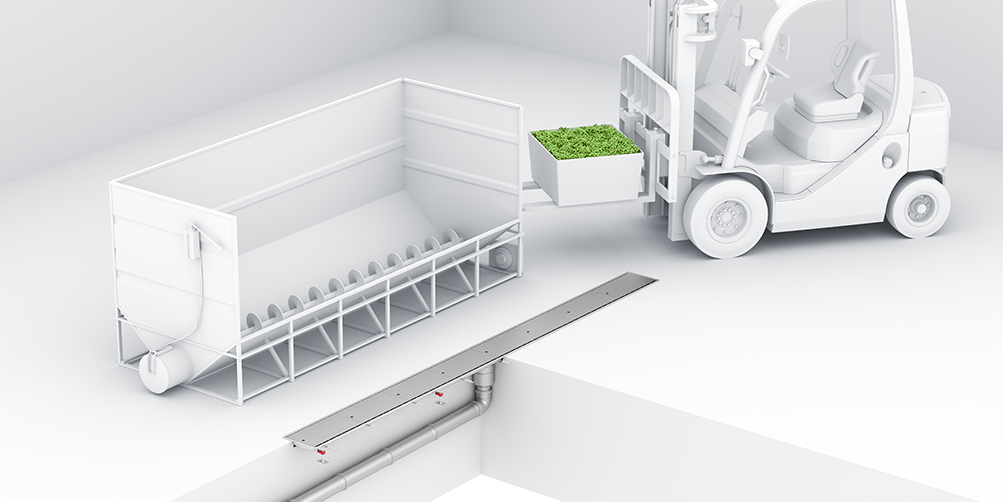

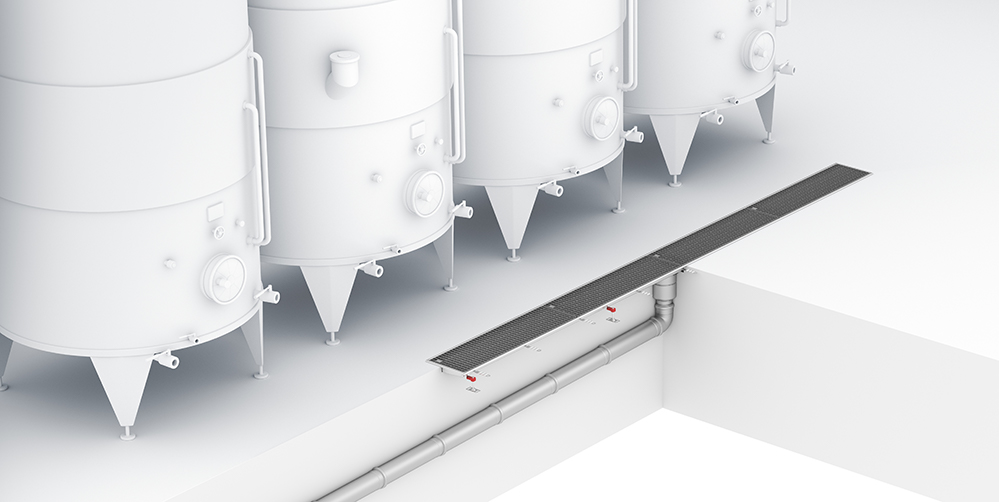

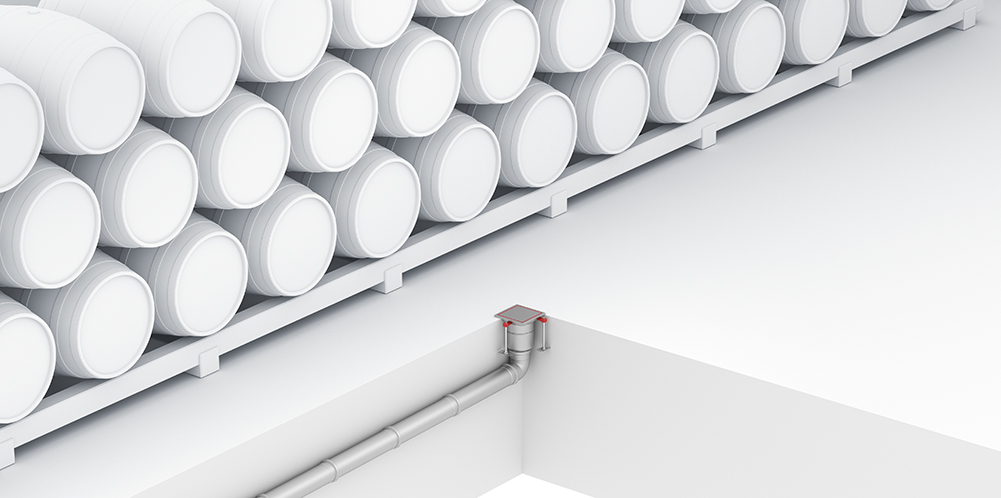

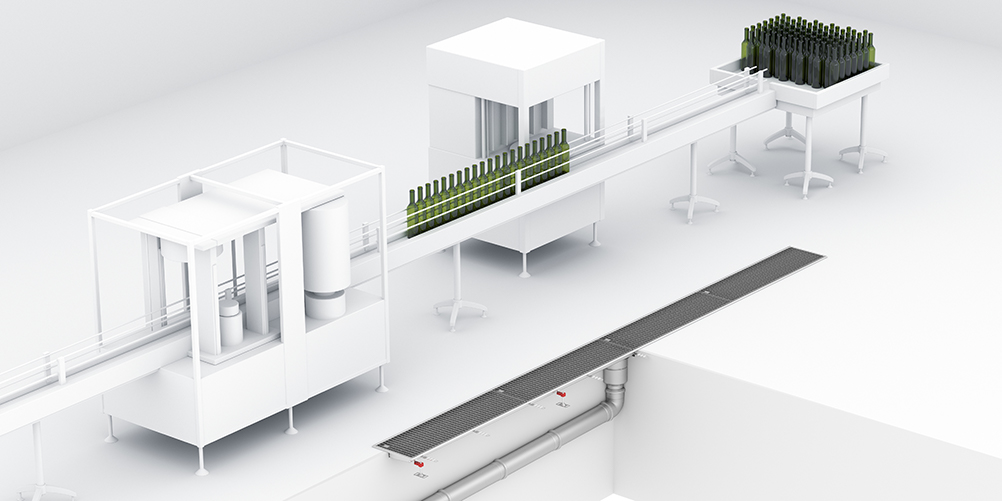

- establishing better production efficiencies and lower operational costs with easy to clean products that complement the aesthetic design of wineries

- enhance product and employee safety

- provide ultimate range of stainless steel drainage products with improved product lifecycle, easy installation, maintenance and warranty for every winery area

- certificated drainage that fulfill all necessary norms and regulations

- full customer care and local support from design consulting to onsite installation support

HygieneFirst

ACO’s commitment to optimal hygienic performance

Technology and craftsmanship are at the heart of our business. ACO has extensive experience with drainage product development and manufacturing, making it our core competence and part of our company’s DNA. ACO employs extensive research and innovations in product development. From initial design to final surface treatment, we secure the quality to deliver the optimal hygienic drainage.