Industrial Drainage for Dry Processing Facilities

Dry manufacturing processes requires more than just drainage – it demands control. Dust, dry waste, and biological residues must be handled in a way that protects both the product and the people. At ACO, we understand the unique challenges of dry production areas in the food and beverage industry or pharmaceutical production. ACO offers closed channel systems, specifically designed for dry processing zones.

However, even dry areas often require periodic wet cleaning for deep sanitation. When this happens, reliable and hygienic drainage becomes essential – and the wrong drain can compromise your process.

That’s why ACO systems are designed to meet the full range of demands in dry processing environments:

- Odour-proof solutions

- Separation of biological materials

- Sufficient drainage capacity

- Antislip floor integration

- Outstanding cleanability

Recommended Products

ACO hygienic box channel

The ACO hygienic box channels provide easily cleanable and fully inspectable drainage solutions that are ideal for applications demanding in cleanability as products are capable of handling large volumes of fluid containing solid particles.

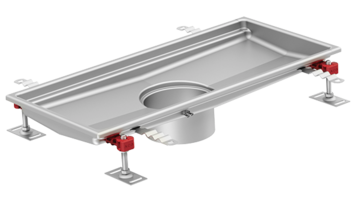

ACO hygienic gully 218

ACO hygienic gullies 218 cater for sufficient flow rates and construction requirements including shallow construction depths. Hygienic features ensure easily cleanable and fully inspectable solution.

ACO pipe

ACO’s stainless steel push-fit pipe system is designed for grey or black water applications. ACO Pipe products offer more than 40 years’ product life thanks to the material properties of stainless steel. Easy on-site installation and handling is ensured by a push-fit assembly system and related cutting tools.

ACO odour proof gully cover

The ACO odour proof gully cover hermetically separates the floor surface above the gully from the space within it. It is designed for hygienically sensitive areas where foul air traps have dried out and a new form of odour protection is required.