ACO condensate drainage for supermarkets

ACO condensate drainage enables reliable dewatering of condensation and cleaning water during the operation of refrigerators and freezers in supermarkets - regardless of building and floor structure.

There are many benefits of ACO condensate drainage in contrast with traditional gravity drainage

- Installation independent of building and floor structure

- Ongoing supermarket operations during installation and maintenance work

- Rearrangement of refrigeration cabinets does not require re-construction of floor

- System components are always accessible

- Self-cleaning effect effectively prevents clogging

- Multiple cabinets can be connected to one collect tank

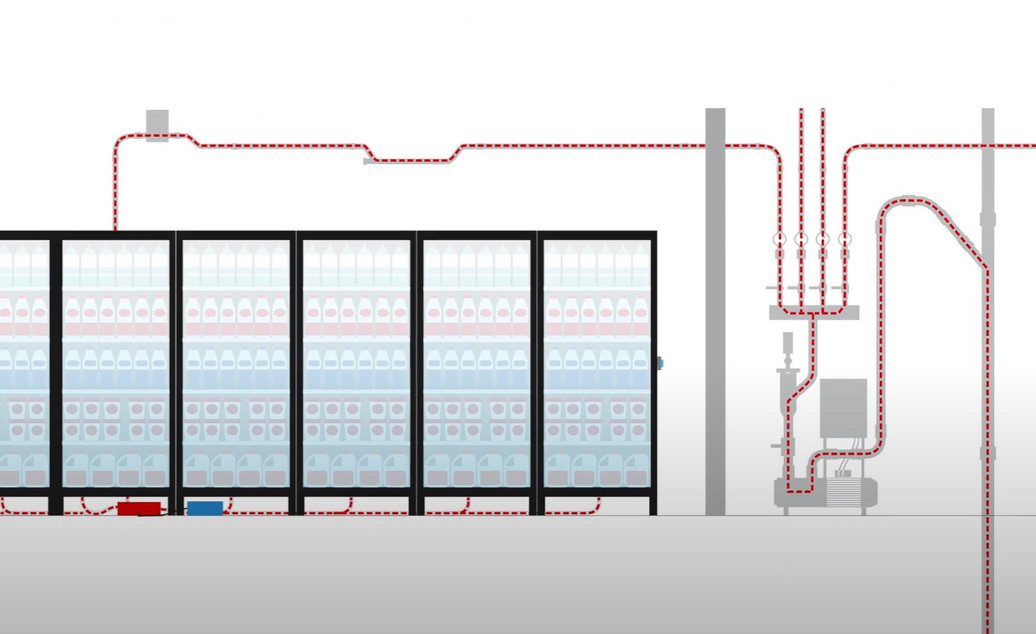

System overview

1. Vacuum pump

- evacuates the pipeline and dewaters the condensate during refrigeration cabinet operation and cleaning

- the system is compactly flexible and independent of the building and floor structure

2. Collection tank

- collects the condensate below the refrigerators and freezers

- directly connected to the refrigerated cabinets with flexible hoses, integrated level sensor monitors the amount of condensate in the collection tank

- Connection to the riser also with flexible hoses, increased accessibility

Conventional gravity vs. vacuum drainage

Condensate drainage of refrigerated cabinets with floor drains and pipe systems

In the gravity drainage of refrigerated cabinets, the resulting condensate is first collected via floor drains that are integrated into the floor structure. The collected condensate in the floor drains is then discharged via pipelines in the floor structure.

The piping systems must have a suitable gradient and transfer the condensate to a suitable collection tank. These collection containers are often also located in the ground structure.

In this case, the installation of condensate drainage must already be taken into account during the planning of soil drainage and soil construction. It must also be ensured that the necessary gradient of the piping systems can also play a role for long distances, so that the disposal of the condensate at the final collection point may only be possible with difficulty, or another lifting device may be necessary.

If, in the course of a redesign of the sales room, the refrigerated cabinets are moved to another location, new drainage points for condensate drainage must be created.

This is associated with a lot of time and financial effort and already existing old drainage systems remain unused in the floor structure.

Disadvantages of gravity drainage in supermarkets

- Piping systems must be laid with sufficient gradients

- Little connection flexibility when changing the spatial arrangements of the refrigeration cabinets

- High effort for the creation of new drainage points, as new floor drains and piping systems have to be reintroduced into the floor structure

Advantages of vacuum drainage system

Installation, connection and drainage

The entire system technology is installed on the prefabricated floor.A major advantage is the connection between the drain valves of the refrigeration cabinets and the collection container:

The connection is made with flexible hoses which significantly simplify inspection and disassembly. Furthermore, by means of a closed collection tank, the dewatering process is extended to the actual accumulation point of the condensate (cooling cabinet drain).

This effectively reduces stagnant water and the formation of bacteria, so that complex biofilm removal by aggressive cleaning agents is minimized.

The operating states of the system technology are displayed visually directly on the refrigeration cabinet (Multi Color Button) and transmitted to the BMS via Modbus. A fault and setting history is also implemented and serves to increase operational safety. The system technology is parameterized conveniently via Bluetooth and smartphone/tablet.

ACO vacuum collection system overview

- The system is installed on the prefabricated floor and can be easily dismantled during later conversions.

- The connection between the drainage objects and the collection tank is made with hoses in a vacuum system, without the need for a gradient.

- Each collection tank can be connected to up to eight drainage connections.

- The dewatering process extends from the collection tank to the drain nozzle of the refrigeration cabinets and thus effectively prevents long stagnations of the condensation water

Fast remodeling and easy planning

When using the collection tank, it is possible to easily connect up to eight drainage items to a collection tank. These eight connections are then connected to a riser line as shown in the figure.

Dewatering takes place via only one vacuum valve installed in the pipeline. It is therefore not necessary to consider individual refrigerated cabinets separately and to dewater them separately via appropriate risers and additional vacuum valves.

This approach reduces the assembly and installation effort considerably, especially for larger projects, as the number of risers can be reduced to a minimum.

Thus, the vacuum drainage system is the perfect solution for the renovation of stores or for new building planning with regularly changing refrigeration cabinet installation.

Services

Installation and Comissioning

The assembly of the entire system technology, the assembly of the fastening technology and the commissioning of the entire system is optionally carried out by our expert assembly team or specialist installers authorised by ACO Haustechnik. All necessary installation steps are carried out in close consultation with our application engineers and the customer's contact persons on site.

Before the start of operation, commissioning and a complete functional test of the drainage system are carried out so that the entire system can then be handed over risk-free to the end customer for regular operation.