Welded pipes vs. socketed pipes in case of an earthquake

Is there a risk of pipe deterioration during earthquake by transversal forces?

Earthquakes pose a severe threat to any pipe systems. They have caused vast amounts of damage, including ruptures and leaks to any kitchen and food processing environments pipelines and distribution systems, ultimately leading to high repair costs and hygienic risks. This has had profound economic and environmental effects on the business.

Picture gallery

In many areas of the world, ordinary industrial stainless steel pipework is being connected by welding. This method might seem financially rational due to low cost of work, but also poses many risks especially in parts of the world where any, even mild tectonic activity might occur.

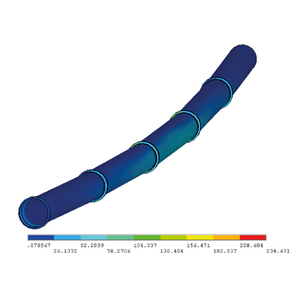

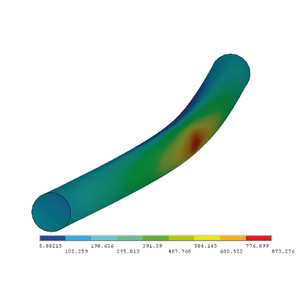

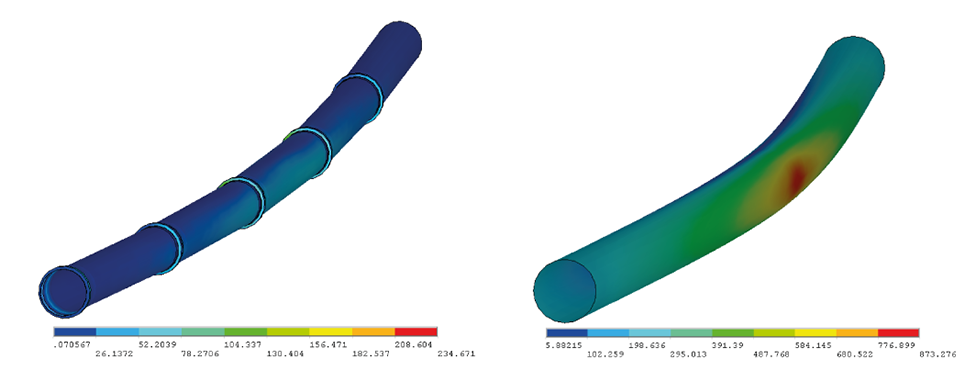

In year 2015, ACO has concluded series of tests which were set to prove that push–fitted pipes are ideal for use in such areas. The results clearly show that push-fit system is much more resilient towards ground disturbance than the pipework connected by welded joint. A longitudinal movement is compensated by the movement of pipe in the socket and tension during a transverse movement is reduced by a slight movement of pipes within the socket as the graph below shows.

It’s obvious from the test results, that the socketed pipe is much more resilient to underground movements caused either by tectonic activity or any other force. The stress that acts on the pipe can be even greater and under laboratory conditions we can observe that long pipeline connected via push-fit can handle greater deformation without damage than a pipeline with welded joints.

ACO pipe | |

Deformation (mm) | Stress* (MPa) |

50 | 56 |

60 | 77 |

70 | 106 |

80 | 142 |

90 | 186 |

100 | 235 |

* Risk of deterioration - Stress > 600 MPa

It’s obvious from the test results, that the socketed pipe is much more resilient to underground movements caused either by tectonic activity or any other force. The stress that acts on the pipe can be even greater and under laboratory conditions we can observe that long pipeline connected via push-fit can handle greater deformation without damage than a pipeline with welded joints.

The ACO pipe push-fit offers many other advantages

ACO pipe push-fit connection is reliable for vacuum and gravity piping systems. ACO pipe double lip seal delivers the ultimate system reliability. The unique and sophisticated design of lips and cavities provide tight connections.

Benefits Of Push Fit Fittings

- The speed of installation with push fit fittings is the biggest advantage. In an emergency, repair of a pipe by simply pushing on a push fit fitting.

- Push fit system is a great way to make pipe connections without need for other ways of connection like welding or bolting.

- The ACO pipe product line includes many push fit fittings in a variety of sizes for any kind of application.