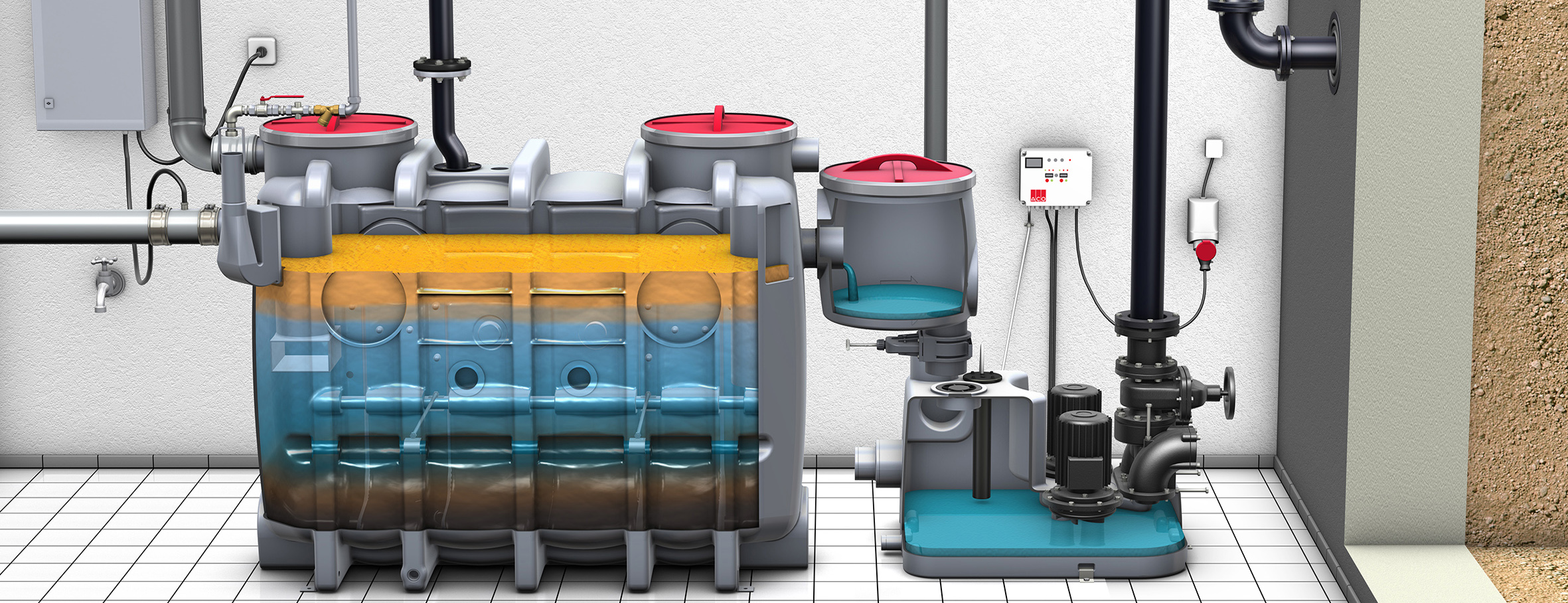

The system for odour neutralisation in grease separators

Malodorous fatty acids are produced by microbial degradation processes in grease separators,. High vapour pressure and low boiling temperatures allow them to transfer from water to gas. The prescribed ventilation of the grease separators via the roof and the requirement to empty them at least once a month mean that unpleasant odours are released into the environment. A big problem both for the catering businesses themselves, as well as for the guests and residents in the vicinity. Odour neutralisation is hereby the solution. ACO Building Drainage has developed a fully automatic system for this purpose.

Picture gallery

According to the 1986-100 standard, companies in which greasy waste water is produced must have a grease separator. According to EN 1825, operators are therefore obliged to empty and clean this regularly i.e. at least once a month. Even when the waste is disposed of by pumping it out, the unpleasant odour that develops between cleaning intervals is not completely excluded: Unfavourably positioned vent stacks, partially leaking pipework systems and floor gullies with insufficient water storage capacity provider loopholes through which the stench reaches the olfactory nerves.

Odour neutralisation creates a remedy - and a system carefully adapted to the size of the operation as well as the expansion stage of the grease separator system ensures automation, low maintenance effort and lower costs. The system for odour neutralisation from ACO Building Drainage comprises a small control cabinet which contains both a time-controlled metering pump and the odour neutralising agent. The required amount of the agent depends on the size of the system and the volume of the fat-containing waste water produced. The pump, which can be adjusted according to individual requirements, automatically feeds the correct metered amount at the correct frequency into the inlet of the grease separator and thereby ensures effective homogenisation. The agent prevents the formation of unpleasant odours without having an antimicrobial effect - it is completely biodegradable, the decomposition process in the grease separator is not disturbed and nothing stands in the way of additional or subsequent biological wastewater treatment. The new ACO odour neutralisation is universally applicable and individually adaptable. The compatibility with the other system components of the drainage specialist ACO Building Drainage enables the retrofitting of existing systems, independent of the respective extension stage.

For additional information regarding the new ACO odour neutralisation, please contact us.

ACO Building Drainage, with registered office in Philippsthal (Hesse) and Stadtlengsfeld (Thuringia), is the specialist within the ACO Group for the sectors for drainage, separation and pumps in private and commercial buildings. As one of the leading suppliers of system solutions, ACO Building Drainage has decades of experience and competence in the field of building technology. It provides planning offices and specialist trade companies with the security of not only having a reliable partner who is equally oriented towards joint success as well as equally reliable in terms of product and service, both in project planning and in execution in the safety-relevant fields of fire protection, sound protection, hygiene and assembly.