The HygieneFirst Series - Blog #1

At ACO we are committed to helping the food and beverage drinks industry put HygieneFirst. We have extensive experience of working with leading manufacturers and last year alone conducted numerous drainage system assessments with some of world’s largest food and beverage companies. This blog is the first of a series of articles we’re drafting to highlight some of the common issues faced when it comes to optimising drainage performance and to share our best practice solutions to them.

Issue No. 1 – Upgrading your drainage to match your improved production capabilities

What’s the issue?

Understandably manufacturers focus on upgrading manufacturing equipment and technologies when they are gearing up for increases in demand or planning for future growth. Much time is spent on areas such as the specification of new processing equipment, re-designed the layout of an existing production facility so it can accommodate new machinery, and the creation of zones to mitigate the risk of cross contamination and make processing and packing easier.

Hygiene and health and safety are of course key considerations, but although it’s now widely recognised that drainage has a major role to play in optimising hygiene, cleanability and related costs, it’s easy for the facility’s drainage system to become an after-thought.

What problems does this cause?

A failure to consider the drainage system at the initial planning stage can cause numerous issues:

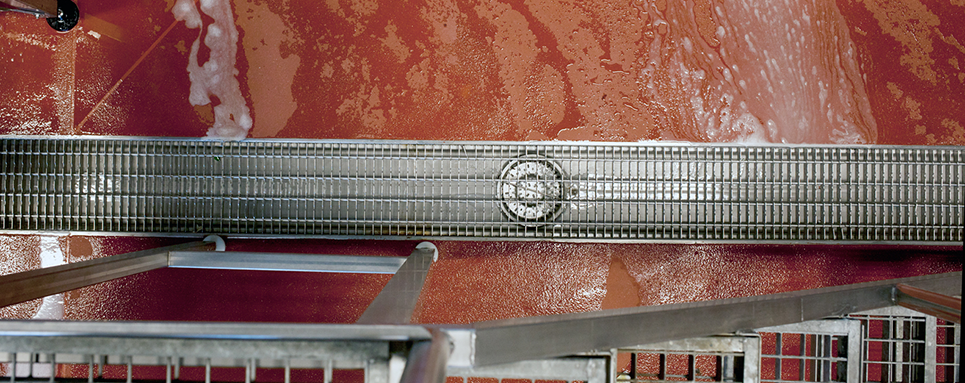

1. The drainage system may no longer be adequate for the increased volume of liquid it needs to handle and liquid may spill onto the factory floor, compromising hygiene and creating a slip hazard for employees.

2. The presence of water and other liquids on the factory floor make effective cleaning difficult if not impossible.

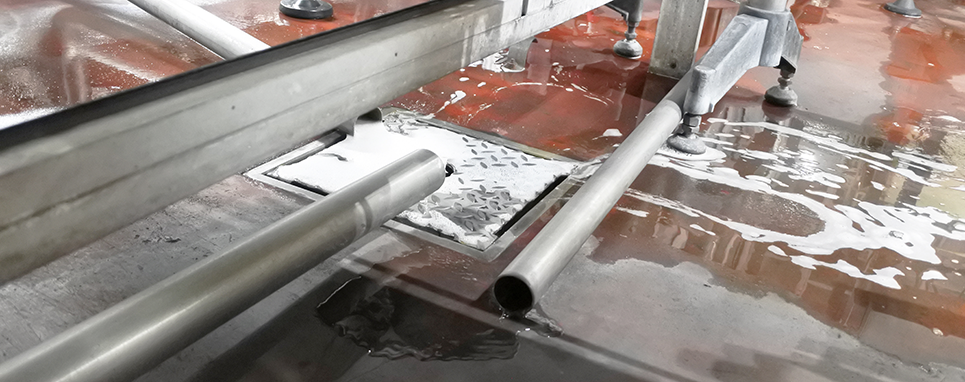

3. When manufacturing equipment is relocated, it can end up sitting on top of the drainage so it’s no long possible to access the drainage for cleaning or inspection purposes.

4. Equipment can be located nowhere near to the drainage that is essential for its effective and safe operation.

5. The hygienic performance of the manufacturing facility is critically compromised.

What’s the solution?

Prevention of this type of issue is not overly complicated – drainage simply needs to be considered at the initial planning stages of any factory redevelopment.

We have five key tips to make this process as easy and effective as possible:

1. Talk to a specialist drainage provider before you confirm the new layout of your production facility. At ACO we have a team of in-house technical design experts who are happy to provide you with the advice and guidance you need to ensure you end up with a high performance drainage system that meets your new requirements. Key considerations include operating temperatures, flow rates and the type of cleaning chemicals which will be used.

2. Make sure any equipment which will need drainage is located near to it!

3. Consider whether the slope of the factory floor needs to be altered to ensure any waste liquids generated flow towards and into the drainage system.

4. Ensure all your drainage can be easily accessed for ongoing inspections and for easy cleaning – a drainage system that can be easily accessed is much more likely to be cleaned on an ongoing basis.

5. Work with your drainage provider to develop an ongoing maintenance and cleaning programme for the updated drainage system so you’re clear about the ongoing costs of your updated drainage system at the specification stage.

If you’re currently planning an upgrade to your food and drink manufacturing facility and would like to talk to our drainage design team, please email us at marketing@aco.cz.