Hygienic design & Drainage: The key things every food company needs to know

by Michal Bačkovský, Business Development Manager for ACO Industries k.s.

At ACO we’re committed to designing and manufacturing drainage that delivers the ultimate in hygienic performance. We’re a long-standing member of the European Hygienic Engineering and Design Group (EHEDG), are the first company to incorporate the hygienic design principles that are normally reserved for food contact equipment into our product designs and our ongoing collaboration with leading research bodies, end users, other industry suppliers and leading academics keeps up to date with the very latest best practice.

Although drainage is not the only thing that affects hygiene in a food processing or manufacturing facility, it undoubtedly has a crucial role to play when you’re looking to prevent cross contamination and optimise hygiene.

So what are the key questions you should ask about the design of your drainage?

Is your design drainable?

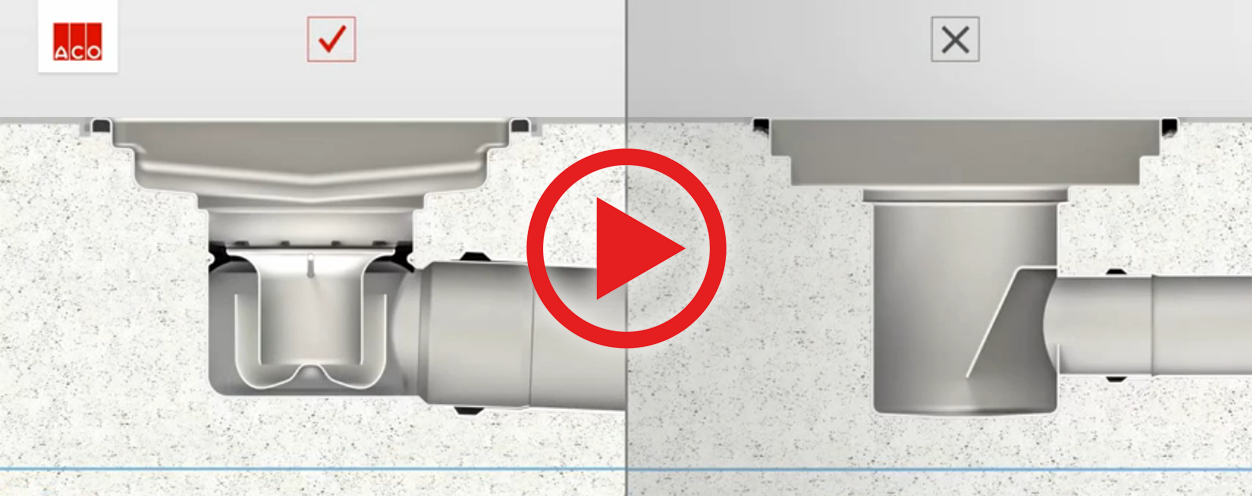

If your drainage isn’t fully drainable then its hygienic performance will be compromised. To optimise hygienic performance, ACO drainage channels have completely drainable dry sumps with engineered positive slopes which prevent the build-up of stagnant water, odours, microbial growth and potential chemical hazards.

Are you using continuously welded lap joints or welded butt joints?

Simply put, lap joints can’t be welded hygienically. When you weld a lap joint you create a void and that void can and will harbour bacteria.

Do your corners feature welds or are they rounded?

Sharp corners are harder to clean, particularly if they’re situated at a right angle or bend in the drainage.

It’s harder to get into a corner and to make contact with its entire surface, which means there’s a very real risk that the corner won’t get cleaned effectively. To ensure every part of the drainage surface is easily accessible and to meet best practice guidelines, drainage should feature rounded corners with minimum radii of 3mm.

If you have to have a weld, is it made in a corner or on a smooth flat area?

If the drainage you specify is welded on a flat area, the manufacturer can ensure the weld is smooth and smooth contours eliminate crevices that can harbour bacteria. It’s a simple step but one that can make all the difference.

Will you have to power-wash your drainage?

In spite of what some companies will tell you, one of the worst things you can do is power-wash your drainage. Power-washing creates ballistic droplets (basically a high velocity spray). This spray spreads the bacteria that were living in your drainage system across an area of up to 20 metres in diameter. So, if you want to spread bacteria around your facility, this is an excellent way to do it! Your drainage should be designed in a way that power-washing is not required. Its design should limit the build-up of bacterial to reduce the amount of cleaning needed. It should also be designed in a way that ensures cleaning is a quick and easy process. Should steel products be fully pickle passivated? Yes! Stainless steel drainage will suffer from corrosion if it is not fully passivated which in turn will lead to a risk that they cannot be properly cleaned.

So, what else makes the difference when it comes to delivering superior hygienic performance?

Well, drainage is only part of the story. Plant operators also need to ensure...

1. They specify drainage products that meet best practice recommendations by applying the same standards to drainage as are normally reserved for food contact surfaces.

2. The floors being specified are appropriate for the area in which they’re situated and they’re compatible with the drainage system. Take the time to do this as the hardest part of the operation to change at a later date is the floor and drainage.

3. There is a well-defined cleaning procedure in place that ensures the right chemicals are used and cleaning takes place at a frequency that’s appropriate to the environment.

4. The appropriate cleaning tools are used and the area(s) in which each tool should be used is clearly defined. By ensuring tools used in high risk areas are not used in low risk areas – or vice versa – operators can significantly minimise the risk of cross-contamination.

5. A strict monitoring regime is in place that’s tailored to the needs of the area in which the drainage is installed. Taking regular swabs in areas that are at risk can ensure that you know it's 'clean'!

When combined with the specification of drainage that’s designed in accordance with the very latest best practice guidelines, these five elements form the pre-requisites for the foundation of a safe HACCP process. All these factors are important