- Integrated ventilation

- Including modular control (Siemens)

- With low maintenance and low-cost plant technology

- With fluidized bed technology (filling body)

Process technology

Industrial or trade wastewater from catering facilities must also be treated by passing it through a grease separator before it is discharged into the public sewers. However, some municipalities require further wastewater treatment for additional protection of the sewer network and wastewater treatment plant. Process wastewater from a large catering kitchen can usually not be precleaned sufficiently by grease separators. ACO has developed further wastewater treatment methods, based on biological or chemical-physical cleaning methods.

For example, where economic efficiency and sustainability factors are concerned, operating costs can be compensated and energy can be saved by using a new type of heat exchange for wastewater from grease separators with output-controlled heat pump.

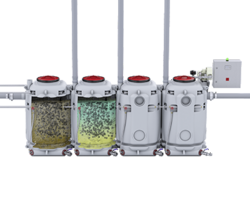

Waste water treatment plant ACO BioJet-P-OM

Chemical-physical wastewater treatment

During chemical-physical wastewater treatment a flocculant is added the organically polluted wastewater (mainly with emulsions of fats and oils plus dissolved components). Through the flocculation that this causes emulsified and dissolved elements are also retained in the separator. This increases the proportion of residues and so the disposal cycle needs to be adjusted to suit.

Heat exchanger ACO LipuTherm

Wastewater as a innovative heat source become particularly attractive where high quantities of waste water and temperatures are present. These two parameters are often found in gastronomy of commercial kitchens and therefore provide optimal conditions for the economic recovery of the heat. Interface for the installation of this technology are grease seperators.